We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

There is nothing more satisfying than learning how to build a canoe on your own. This 12-foot plywood freight canoe is easy to build and sturdy enough to carry lots of gear. Throw some camo netting over it and you can hunt ducks out of it, too. It can be rowed, paddled, poled or powered by a small trolling motor.

The bottom is slightly wider than normal to provide added stability and load-carrying capacity, and has minimal rocker to allow the hull to slip through the water at low speeds. This is not a high-speed vessel, but even the smallest of motors will push the slippery hull with ease. The boat becomes even more stable when it’s loaded, and the 45-inch beam provides ample deck and storage space.

The lightweight versions built with the selected materials weigh between 50 and 60 pounds. The canoe can be car-topped and loaded or unloaded by a single person. And to make launch and retrieval easier, the tough graphite bottom can be dragged over parking lots, launch ramps and portages.

Two large watertight compartments fore and aft provide dry storage, hull reinforcement and emergency flotation should the boat accidentally fill with water. The compartments also provide seating, and vertical braces can be attached to provide support when you’re standing. The compartments are accessed by simple screw-out ports. For storing larger items, a hinged hatch can be fitted.

The seating arrangement presents various options for gear tie-down and passenger loading. With a motor-control extension handle, a single operator can sit near the center of the hull for optimum trim, or the operator can sit on the aft compartment and the hull can be balanced with passengers or gear.

Oarlocks can be attached at any point along the gunwale to allow rowing from any seat. Colored areas on the deck are non-skid surfaces made from epoxy sprinkled with fine masonry sand to provide secure footing when you’re standing or stepping aboard.

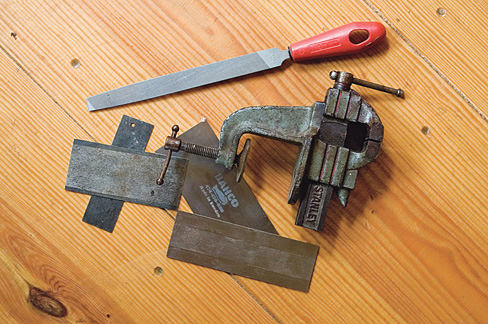

The hull and seats are built from plywood, except for the optional hardwood or softwood trim used for moldings and gunwale laminations. The plywood is sealed with epoxy to provide a tough, slick surface that won’t waterlog and is easy to maintain over the long term. Hull components are pre-finished before assembly; after assembly, the hull can be painted or varnished to a natural color. Epoxy is used to join ply panels with doubler pads. No exacting woodwork is required.

Hull seams are covered with a strip of fiberglass tape on the exterior and a bead of thickened epoxy on the interior. Aside from screws used to attach hardware, no metal fastenings are used in the hull. Plywood compression pads are laminated onto the transom to provide additional support to the motor mounting. The plywood-and-epoxy construction technique is well suited to novice boat builders and simpler than traditional wood methods.

The 30-page building plans are written for amateur builders and include photographs and sketches, material sources, step-by-step instructions and discussion of the many options. Plans cost $39 and are available from butlerprojects.com, or send a check or money order to Paul Butler, Box 1917, Port Angeles, WA 98362.

»3 panels 6 mil hardwood ply, or 1-inch-thick softwood ply, for bottom panel, decks, transom, optional seats, motor mount compression pads and doubler pads.

»4 panels 4 mil hardwood ply, or 3⁄16-inch-thick softwood ply, for topsides, bulkheads, doubler pads, etc.

Note: As detailed in the plans, lightweight versions require different plywood types and trim wood from standard-weight boats. All standard ply panels are 4 by 8. Trim Wood

»4 to 6 hardwood or softwood gunwale strips, 1⁄4-inch thick by 11⁄2 inches by 14 feet. Middle seats may be plywood or timber planks, and extra trim may be applied as desired to bow and transom corners. Epoxy And Glass Tape

»2 gallons epoxy resin with catalyst selection of epoxy fillers for thickening and sandable fairing compound.

»70 lineal feet of 3-inch-wide fiberglass tape.

»Masonry sand for non-skid surfacing.

»Foam rollers, disposable foam brushes and rubber gloves. Material Sources

»Marine/boat hardware, boat-building supplies and gear: duckworksbbs.com »MotorGuide trolling motor: motorguide.com »West System epoxy: westsystem.com Paul Butler

The Flathead Lake freight canoe is easy to build and will haul piles of gear or a couple of passengers.