It is my firm belief that every hunter and trapper should own and know how to use a fleshing beam. This imperative stems from another firm belief: that every hunter or trapper should know how to flesh and prep the capes and hides of the animals they kill.

Any hide or cape that will be mounted or put on the fur market needs to be fleshed. It is true that in a pinch, many hides can be fleshed with a knife on a table or over your knee, but unless you really know what you’re doing, you’ll usually end up with a pretty pitiful finished product. And sometimes a laceration on your leg.

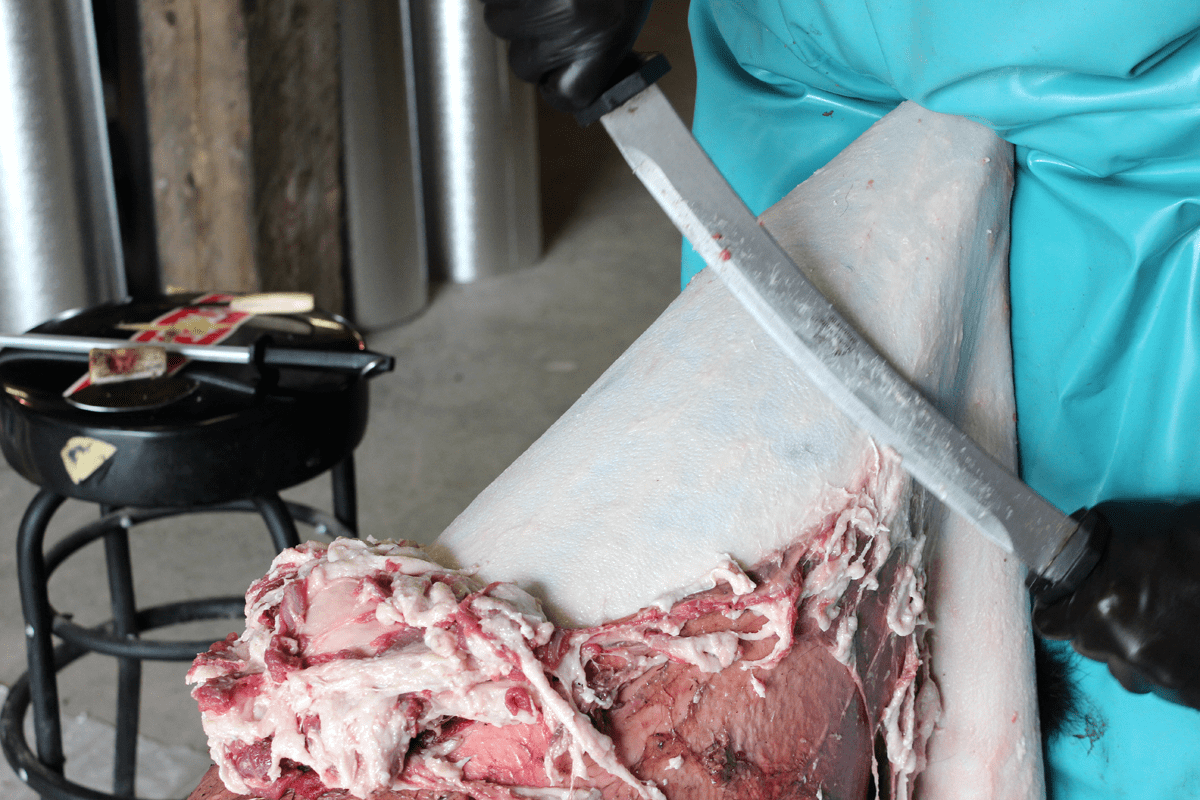

I won’t speculate as to how long the fleshing beam has been around, but the concept has stood the test of time. The principle is to provide a hard, smooth backing surface for a skin to be placed on (hair side down), so that the fat and meat can be scraped or shaved off uniformly and efficiently. There are various beam configurations and a wide variety of fleshing tools used by different folks, but the principal is the same. Having that hard smooth backing compresses the hair and stretches the skin taught, allowing the weaker connecting membranes and fat to be scraped off clean.

Typically, fleshing beams are made of wood, preferably hardwood, shaped and sanded to fit the user’s needs. The issue I have found (primarily when fleshing furbearers) is that imperfections in the wood are very difficult to eliminate, and even if perfect, the texture and sponginess of the wood cause some difficulty in smooth and uniform scraping. My buddy Garrett turned me onto PVC several years ago when he demonstrated his new fleshing beam on river otters from Afognak Island. The beam, made from a section of PVC pipe, was much smoother and harder than wood, and made fleshing much easier than with the wood beam I was using at the time. Using a draw-style fleshing knife (I use a Necker 600), the flesh seemed to roll off with much less work, and resulted in a much more uniformly fleshed hide. I quickly made one for myself, and couldn’t believe how much easier it made my life. I was able to flesh everything from foxes to wolves and wolverines in half the time.

I do use a large spruce fleshing beam for big-game animals like bears, sheep, caribou, and moose. The 8-inch-diameter beam allows me to work on a much larger area each time I move the hide and many big-game animals have much thicker hair and skin than furbearers do. All that hair generally nullifies small imperfections in the wood beam. However, for an all-around beam, PVC is great. Most, if not all furbearers have thin enough skin and light enough hair that the difference between wood and PVC is huge.

MAKE YOUR OWN PVC BEAM

Since the designs of fleshing beams are as different as the people who use them, I can’t say what the universally perfect fleshing beam is. For me, it’s angled up from the ground at around 45 degrees, with the point at hip level. If you know some folks who use different methods of fleshing or beam configurations, try them out and see what fits you best. To make a PVC beam, simply cut out a section of pipe that will fit the curve of your drawknife relatively well. I use a section of 6-inch pipe, but 8-, 10-, or 12-inch will work just fine. Cut out a piece of the pipe to act as your convex-shaped fleshing surface, I attach that to a wood frame with countersunk screws. I fill in the screw holes with epoxy and sand them smooth.

Dimensions of your beam depend on the size of the animal you are fleshing. You want to cut the section of pipe wide enough so that you will barely be able to fit the body of the smallest animal you want to skin, and then taper it nearly to a point so that the head of that animal will just fit on the beam. Once you attach the PVC pipe to your beam frame of choice, you are ready to roll, literally.