We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

The gunsmith has long held a revered place in American firearms lore. But the rise of the AR has ignited a fierce debate in gunsmithing circles, with some suggesting that artisanal skills are in decline due to the popularity of the “Lego gun.” Others, like Bob Thacker, director of the Pittsburgh Gunsmith School, say there has been “exponential growth” in the craft of the gunsmith since 9/11. He has a two-year waiting list of potential students, a third of whom are veterans.

But who are these artisans bent over benches and vises who make your gun feel so good in the palm of your hand that it’s like greeting a friend, who get your rifle to split the bull’s-eye, or who create a trigger pull so slick it’s like oiled glass? Here are four craftsmen who represent different facets of the modern American gunsmith.

Paul Chapman

Head Gunsmith, Griffin and Howe

The Griffin & Howe store at 589 Broadway in Lower Manhattan has been a storied bastion of bespoke firearms for America’s ruling class starting in the 1920s. It was frequented by the Vanderbilts, the political dynasty of the Bush family, and Ernest Hemingway, who bought a rifle in .505 Gibbs. And it was where apprentice gunsmith Paul Chapman saw a trainee engraver on his first week of work nervously putting a lavish $30,000 Purdey shotgun in a vise, barely tightening the jaws, so afraid was he of damaging it. When he began working on it, the gun tumbled free and the stock broke right in front of one of the company’s vice presidents. “For every trainee gunsmith like myself who dreamed of working with high-grade guns,” says Chapman, “this was the biggest nightmare.”

It was 1979, and Chapman was a wide-eyed 19-year-old from Brooklyn with a passion for firearms by way of his uncle’s gun store in rural Vermont. At age 11, he applied naval jelly to his father’s rusty antique guns—stripping off the rust but also the bluing—in his burgeoning passion for gunsmith work.

The fourth-floor workshop at Griffin & Howe, where Chapman stood with eight others along a long bench, was where new artisans honed their skills. One of Chapman’s first jobs was to make up the bluing formulas in boiling vats. Sometimes they would overflow and drip down between the floorboards onto a furious architect’s drafting tables on the floor below.

Chapman’s colleagues were an eclectic bunch. One diminutive Italian man who worked with gun barrels had learned his skill with metals by taking the dings out of torpedoes during World War II. Chapman’s mentor was Joe Sovenyhazi, a frail Hungarian who grew up in his family’s gun store and who suffered at the hands of the Germans during WWII. Sovenyhazi was captured twice, once by Americans and then by the Russians, escaping both times. Later, he got to the U.S. after defecting while a musician with a Hungarian orchestra. Sovenyhazi’s skills were so advanced he could make any piece of a gun, and do so with exquisite attention to detail.

Chapman was such a studious apprentice that he would take home the more mundane work of polishing barrels and making rings so that he could be given more important tasks to further hone his skills. Four years after starting at Griffin & Howe, he built his first gun, a .22 Hornet. He went on to adapt a Webley double-barreled shotgun into a double-barreled rifle, constructing the ribs from solid blocks of steel.

Today, 40 years later, Paul Chapman is head gunsmith at Griffin & Howe, leading a team of seven. He is, according to the company historian, the “personification of Griffin & Howe.” Recently he made a series of six guns for the Safari Club anniversary in calibers ranging from .22 Hornet to .416 Rigby, the set worth around $350,000. “Today in the high-end market, you’ll see a lot more engraving, a lot more bling,” says Chapman. “The old Purdeys and Holland & Hollands were understated and subtle guns. But since the mid 1950s, you’re seeing more ornate guns with bright finishes instead of case-color hardening.”

The store is still slammed with work—more so now that they are producing a high-tech line of long-distance rifles on Griffin & Howe chassis-style stocks. The rifles are designed with the close involvement of marksmanship instructor Eli Stulmacher, a former Navy SEAL sniper.

“There’s still a clientele for a hand-built gun,” says Chapman, “even though a lot of this generation doesn’t want well-made, hand-me-down furniture. They want new. They want IKEA. But we can work on and repair anything that we’ve sold, and we can fabricate parts like hammers, springs, pins, and screws. That’s what made us famous.”

Michael V. Loder

Head Gunsmith, Bass Pro Shops

Every year, just two days before Missouri’s deer opener, Mike Loder’s window at the Bass Pro store erupts with a small army of hunters in panic mode. Mike’s steely calm takes over. He never scolds any of the procrastinators for failing to take care of their gun problems during the year. He attempts to diagnose the gun on the spot using an adage that has served him well in his 37 years as a gunsmith: “The customer is always right, but not always correct.”

Generally he finds broken firing pins, faulty springs on the extractor, corroded chambers, or damaged muzzle crowns that affect accuracy. Or, in one case, where an agitated hunter’s semi-auto Remington wouldn’t fire after a long, cold day in the duck blind, he found a miniature Nestlé Crunch wrapper wedged between the sear and the hammer, preventing it from releasing.

A flagship Bass Pro store pulls in shooters from every background and level. Loder’s job is multi-faceted, but largely what’s key is his ability to relate to his customers on a personal level, a skill he found he had when he started at age 20 at a gun store in Houston, Tex. He also deals with a multitude of guns, ranging from the most recently released H&K polymer pistols to 19th century rifles. On the day we spoke, he had an 1873 rifle on the bench with a trigger that wouldn’t work. Unlike with a Glock, there are no exploded diagrams of the trigger assembly, and with 140 years of gunk in the action, remedying the problem was a challenge. “When we looked on the internet, we read about other guys who had the same gun and the same problem, but they had been too aggressive and broken a part during disassembly,” he says. “With modern guns, you can just replace a part, but with something like this, a broken part is a real headache.” Loder—putting himself in the mindset of a 19th-century gunsmith who didn’t have spare parts or diagrams—cautiously took off the sideplates, cleaning as he went, and finally managed to make the gun functional.

Loder has witnessed the paradigm shift toward tactical shooting, a cultural turn from the hunters who had been his core customers. “Because the production of guns now is focused on a more modular design, we’re fixing four ARs in the time it took to sort out that old 1873 rifle,” he says. “Because of that, we have a lot more money going into the till. Back in my day, young men hot-rodded Chevys—now they do it with ARs.”

But old-school skills still count. Loder recently completely restored a side-by-side “hardware store” shotgun for more than it was worth because it had been in a family for generations and the father wanted his son to have his grandfather’s gun. And Loder’s encyclopedic knowledge is highly sought after. A customer came in with an early 1903 engraved factory Colt that had been lying around in his grandfather’s house for years. Loder told him it was worth $20,000, to the customer’s astonishment.

His greatest joy, though, is bringing new shooters into the fraternity, like the boy who came in with his father, carrying the old .22 the boy’s father had learned with but that no longer functioned. Loder got the gun working again and placed the boy on the store’s range, opening up a whole new world for him. The boy turned ecstatic when he hit the bull’s-eye after several attempts. “The happiness on his face was indescribable,” says Loder. “That’s the best part of my job.”

Dave Gregor

Former Seal Team 6 Gunsmith, Now A Manufacturer of High-End Custom 1911 Pistols

High above the fast-moving current of the Allegheny River, then 21-year-old Dave Gregor daubed paint on Pittsburgh’s 16th Street Bridge, but his mind was elsewhere: He was dreaming of the lavishly engraved Purdeys and Holland & Holland shotguns he’d handled as a hunting-obsessed teenager. In his youth, he’d worked the skeet and trap ranges at the Rolling Rock country club, home to America’s billionaire tycoons, like the Mellon family, in the hills of western Pennsylvania. A few months later, it didn’t take much to convince his wife that he wanted to leave the dangerous world of bridge painting to attend the Pennsylvania Gunsmith School. “When I graduate, we’re going to buy a house near Rolling Rock and I’m going to fix all those rich guys’ shotguns,” he declared.

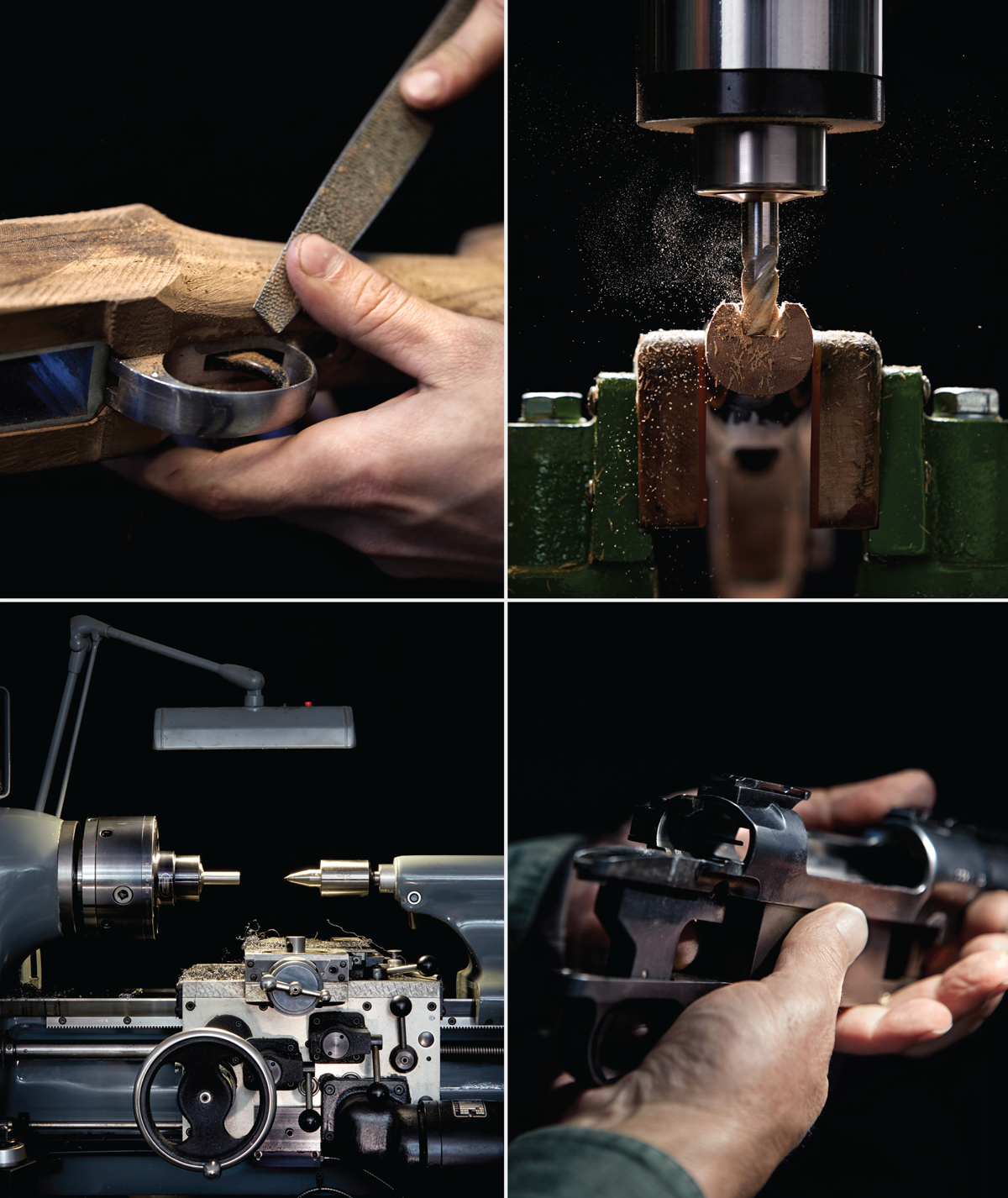

For two and a half years, Gregor was an eager disciple of legendary gunsmith George “Chief” Thacker. But upon graduation, rather than working at Rolling Rock, he was offered a job at Atlantic and Pacific Arms in Virginia Beach. There he was thrust into a world way beyond his initial goal of high-end sporting shotguns. Everyone in the South carried semi-automatic pistols, a culture he’d thought of as “slightly wacky” until that point, and he found himself repairing pistols. It wasn’t long before he decided to build his first 1911, practicing on a piece of round steel that had the same diameter as a 1911 front strap. “My first checkering job was hideous,” he says, but he was a fast learner. Notably, he realized most shooters flinch, so he wanted to develop a trigger that was so glassy-smooth a shooter wouldn’t know when the hammer would fall.

Gregor’s fast-developing prowess drew the attention of a group of chiseled young men with long hair and an acute ease with firearms who regularly came into the store. They sought his help with suppressed submachine guns. Gregor soon discovered that his new clientele were SEAL Team 6 commandos. In time, they were so enamored of his work they wanted him to become SEAL Team 6’s gunsmith. In 1982, Gregor was hired by the Navy and became immersed in the world of the delayed roller lock bolt on Heckler & Koch MP5s and the theory of blowback operation on Thompsons and MAC-10s.

He also came to a startling realization: If he made any mistakes in his work, it could cost one of the SEALs dearly. “I took it so seriously, I couldn’t sleep at night sometimes,” he says. “I wanted to design things that had never been seen before. I like pretty guns, but SEAL Team 6 couldn’t care less about aesthetics—they just wanted them to work.” The teams returned from missions asking for adjustments to their weapons after explaining what had happened. Guns needed to be tweaked, sometimes after combat swims in saltwater. “The creative juices flowed,” says Gregor. “In a combat gun, the tolerances have to be a little looser.” Gregor opened up the guns so that they would work more reliably in hostile environments.

After five years with the SEALs, Gregor moved to the Department of Energy, where he maintained 1,000 weapons used to protect nuclear facilities, and later worked as master gunsmith for the FBI’s Hostage and Rescue Team, where he built 1911s and M16s.

But it was when Gregor moved to the private sector and was free to build his own custom 1911s that his creativity was given free rein. Gregor will spend days creating a gun in which, among other things, the slide-to-frame fit and the barrel-to-slide fit is perfect, and the pieces slide like oiled ice. “When you make a gun on a production line, time is money,” says Gregor. “On a custom gun, I take the time to make it perfect.”

Recently Gregor started working with celebrity Jesse James, onetime car customizer and former husband of Sandra Bullock, now owner of Jesse James Firearms Unlimited. Gregor recently made some 1911s using Damascus steel for a striking marbled effect. “A gunsmith has to be a metallurgist, a welder, a machinist, a mechanic, and a cabinet maker,” says Gregor. “That differentiates a gunsmith from an armorer.”

Chris Peters

Customer Service Manager, Ruger

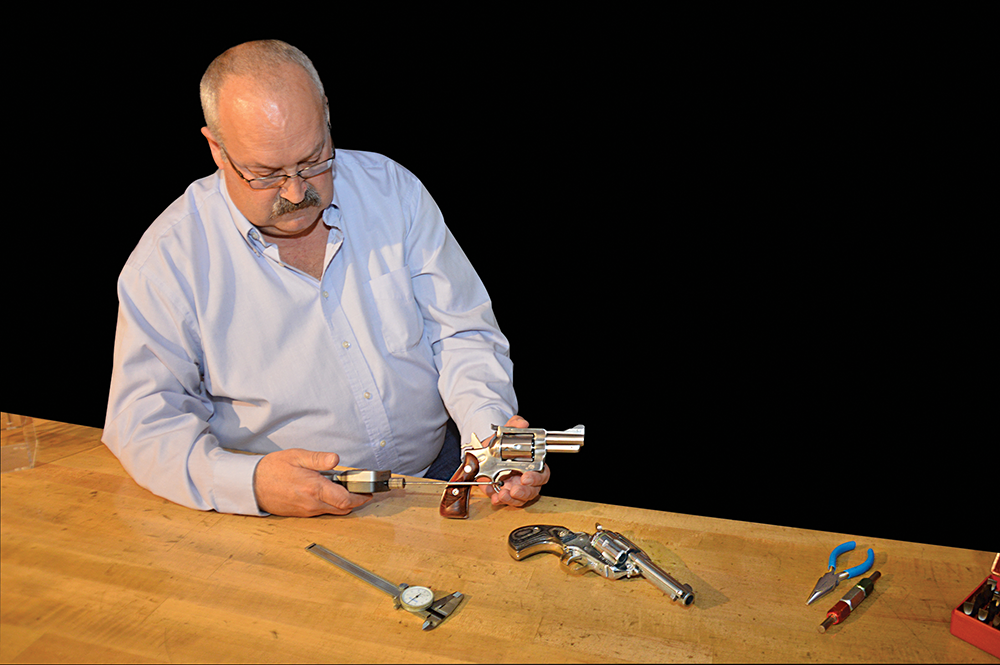

Chris Peters has handled thousands of Ruger 10/22s, Red Labels, and Mini-14s in his time. And he can tell you just from the sound of the snap of the hammer the problem with your Ruger, before even opening it up. “I’m like the doctor who, before doing any blood work, can tell just by the color of your skin or looking down your throat what is wrong with you.”

In 34 years, gunsmith Chris Peters has worked almost every single job at the Ruger factory in New Hampshire, from handgun builder to quality assurance technician to prototype constructor, though he began in repairs. He is a true all-around gunsmith.

He first walked through the factory doors in 1982 at age 20 after graduating gunsmith school in Colorado to join an 800-strong workforce, much against the wishes of his insurance salesman father, who wanted him to accept a sports scholarship at the University of Connecticut. Earlier, at the age of 12, Peters had been entranced by the campfire tales he had been told on hunting trips to Maine, and by age 14 he was refinishing stocks and rebuilding guns. Within weeks of starting at the factory, Peters met Bill Ruger himself, dressed humbly in a flannel shirt that was missing a couple of buttons. It was an especially memorable meeting for young Peters because the great American gunsmiths he worshipped, like Samuel Colt, John Browning, and Oliver Winchester, were all dead, but here he stood in the presence of a living legend. A few days later, Ruger showed the eager young apprentice into his office and eased out his 3-foot-wide office drawer. Inside was the original drawing of the Super Redhawk that later went into full production.

Over the years in different departments, Peters mostly thrilled to the magic that took place on the big 6-foot-by-6-foot drawing boards, where the new guns were created. Once Bill Ruger had approved a design, nothing could be changed. Peters played a key hand in designing the GP100 revolver. “When it came off the production line, I saw 400 of them in racks,” recalls Peters. “It was amazing to be able to walk over and pick one up.” Peters helped design many other guns, and put barrels through rigorous tests at various thicknesses and lengths to find the optimum. One of Peters’ favorite positions was working for research and development. They’d show off some of the designs at the annual Shot Show with private viewings. If the market was right, they’d turn them into production models. The Super Redhawk Alaskan started as a snub-nosed curiosity but found its way to market.

Putting a gun into production is about efficiency, time management, and accuracy. A machinist who hasn’t been trained properly can disrupt an entire day’s production. In the late 1980s, a production line of blued 20-gauge Red Label receivers hadn’t been built correctly. The entire day’s work had to be junked.

In 2000, Peters left to do more custom work with Lewis Arms. There he was slammed with 14-hour workdays, but his work came to the attention of handgun maestro Massad Ayoob, who wrote about some of Peters’ advances, like tweaking two production pistols so that they would operate exactly the same. “One would open and close easier than the other, and I’d have to make them identical. It took forever,” he says. Over the years the manual work of gunsmithing took a toll on Peters’ body. Unbearable pain meant he could no longer do the work he had been so passionate about all his life. He took a rest, underwent physical therapy, and eventually was invited back to Ruger by Bill Ruger Jr. Today, as the company’s customer service manager, Peters supervises a staff of 40, including 16 repair technicians.

Back when Peters started, Ruger made a million guns a year—now it produces 3 million. Ruger was slow to adapt to the big clunky computers of the 1990s, but it made the transition. And now, rather than stockpiling inventory, the company makes only what is ordered, having adopted a philosophy of lean manufacturing.

There are now 1,200 workers, 400 more than when Peters started, and there are plants in Arizona and North Carolina, too. “It’s about constant improvement,” says Peters.

Photographs by Ty Cole