We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

There’s never a better time to test something like Hornady’s high-speed, 3-in-1 case trimmer than right now, in the forty-below doldrums of a Fairbanks, Alaska winter. Case prep is an often despised necessity for reloaders, especially high-volume shooters. Bags, buckets, and boxes full of dirty cases that need to be sized, trimmed, and cleaned offer little gratification. So any tooling that speeds up the process is welcome. That’s where this motorized case trimmer comes in. I’ve churned through over 3,000 pieces of brass in the past few weeks, preparing for warmer days on the range, and I really like this trimmer. Here’s everything you need to know about it.

Hornady High-Speed, 3-in-1 Case Trimmer

Pros

- Fast and quiet motor

- Simple and user friendly

- Includes collets and pilots for most common cartridges

- Precise and consistent cuts

- Trims, chamfers, and deburrs in one action

Cons

- Expensive

- Sometimes cases spin in collet

Key Features

- Twist-lock collet case retention

- Two included collets

- Interchangeable cutter pilots and adjustable blades

- Trims, chamfers, and deburrs in one step

- Eight included pilots

- Direct-drive motor

- Positive-click adjustments on depth stop

- Case collection tray

- Price: $620

I Trimmed over 3,000 Cases, Here’s How It Went

I received the Hornady high-speed case trimmer this fall and have been putting it to hard use these past few weeks. A combination of the bitter cold snap and my limited mobility following my horse wreck back in October provided the motivation for me to chew through a pile of cases that needed attention.

I have sized and trimmed over 3,000 pieces of brass in several cartridges including .30 Carbine, .300 BLK, 22 ARC, 22 Creedmoor, 6mm Creedmoor, 6.5 Creedmoor, 25/6.5 PRC, .280 AI, and .30/06. Through all that, there really isn’t much to report. The motor runs fast and quietly, cases trim rapidly, and it’s generally a joy to operate. I’ve found that adjusting and swapping hardware to be easy and intuitive, and there hasn’t been many things to complain about.

Trim Consistency

The Hornady high-speed case trimmer has been easy and intuitive to set up and operate. It cuts brass with excellent consistency. I tested this by trimming and measuring 30 pieces of 6.5 CM brass in a row. I ran the machine exactly how I have been when processing bulk brass, which is to say, quickly. My goal was a trim length of 1.910 inches, and my trimming averaged 1.9098 inches. The extreme variation was from 1.909 inches to 1.9115 inches, or .0025 inches total. The standard deviation of case lengths was .0005 inches.

Potential Issues

On occasion, the collet won’t get a good grip and the brass will spin with the cutter. Sometimes this seems to be because of debris accumulating in the collet, other times it’s because I didn’t install the case quite right. Some instances could be due to rim diameter or the collet simply not being tightened enough. Considering the volume successfully trimmed on the first try, it’s a pretty minor inconvenience.

I have found the cutter easy to reconfigure with different pilots, but I’ll be curious to see how long the cutter blades stay sharp. Because the blades contact the cases in the same spot regardless of pilot diameter, they will likely need to be replaced eventually.

Electric Case Trimmers — The Competition

There are two dominating styles of motorized case trimmers on the market. One uses pre-set or adjustable bushings into which the case is inserted and held against the cutter by hand, the other uses a collet to hold the case in a sliding assembly which can be pressed onto a spinning cutter.

One example of the first style is the Frankford Arsenal Case Trim and Prep Center. It’s fully adjustable to trim nearly any shouldered case, and features tools for deburring and chamfering. Lyman makes another example that uses pre-calibrated bushings. These are both affordable and helpful for average reloaders — I’ve prepped many thousands of cases with the Frankford Arsenal model.

One of the best, and the first motorized trimmer I ever used, was a Giraud Power Case Trimmer. These trim, chamfer, and deburr in one step, with a belt-driven, high-speed motor. They are an excellent choice, but require specific case holders for each cartridge that run about $45. Downsides of this style of trimmer are that your fingers can get pretty worn out while processing a lot of brass.

One of the best and most well-known trimmers of the second style is the Henderson Precision Gen 3 Case Trimmer. Hornady’s high-speed case trimmer is of the same style and shares some significant similarities, but also has a lot of key design differences.

How the Hornady High-Speed Case Trimmer Works

Hornady’s trimmer comes with good instructions and is easy to set up and use. The unit bolts to your reloading bench via two mounting holes and can also be used with a variety of modular mounting hardware. I simply bolted mine to the bench and can remove it for storage when done.

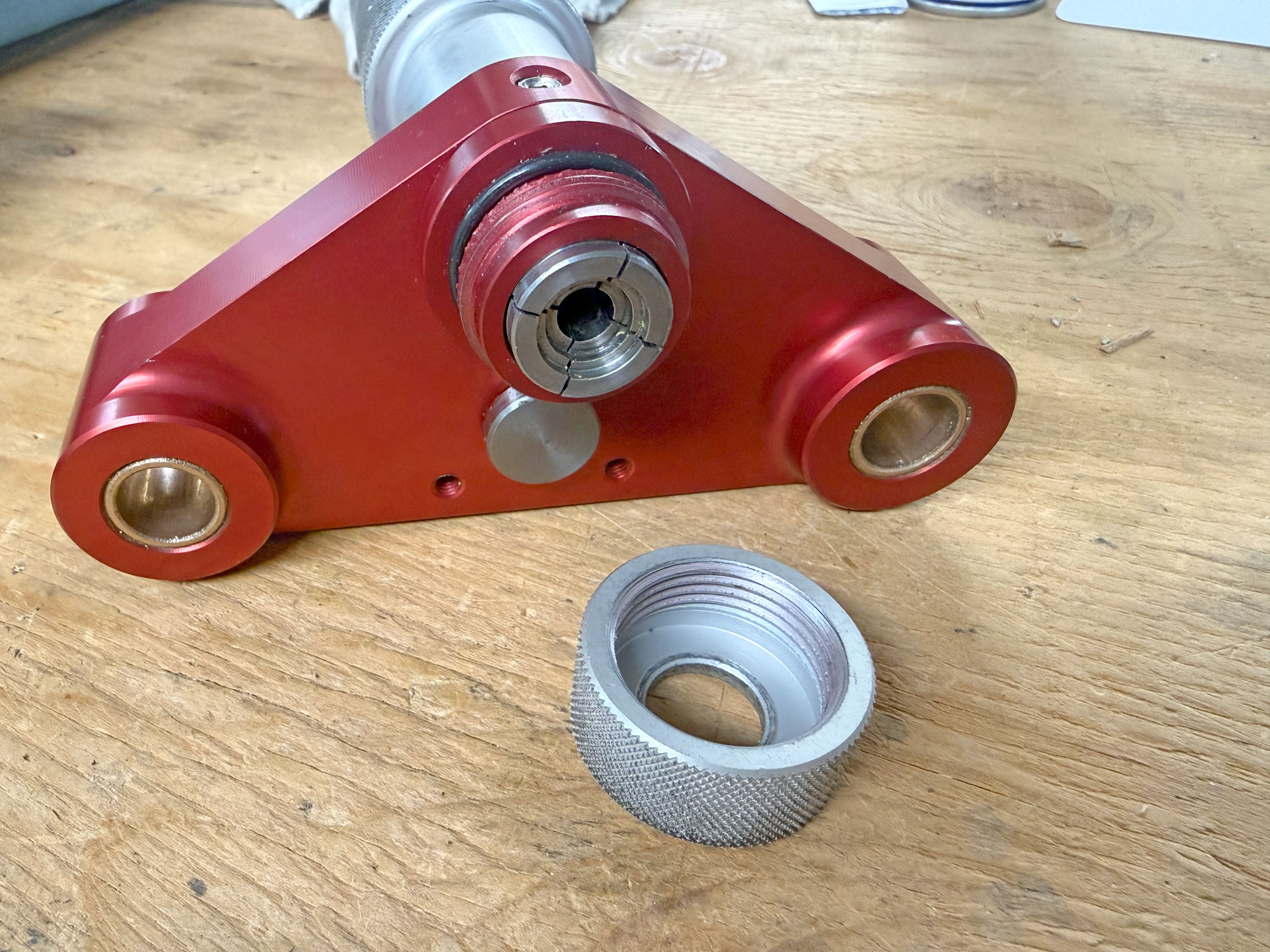

The trimmer comes with two collets, each accommodating two sizes of brass, that cover most cartridges from small rifle to magnum case heads. The collet is installed into the sliding handle assembly and held in place by a left-hand-threaded cap. The large aluminum handle on the back is used to tighten the collet and grab the case rim.

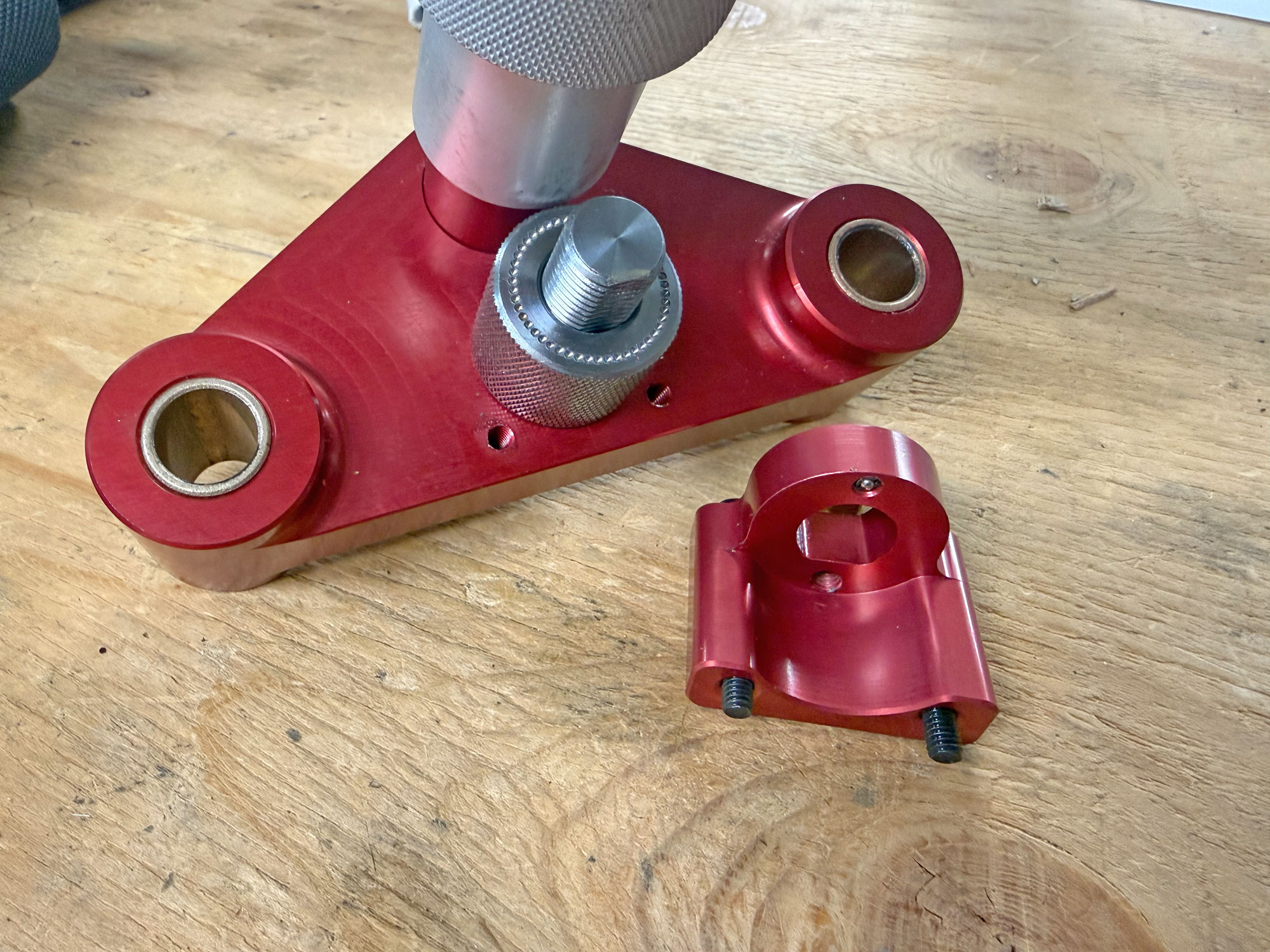

To set up, install the proper collet and fit the case head into it. When set properly and snugged up, a short quarter- to half-turn will secure the case. The handle assembly slides forward and backward on two rods towards the motor and cutter. A hard-stop bar that also slides along the rods in front of the handle assembly can be moved to set the rough depth of your cut. It’s secured in place with two knurled-knob brass set screws. Fine adjustments are easily made via an aluminum knob under the handle, which controls the depth of a plunger that contacts the stop bar. This knob has detents which interface with a small bearing and allow approximately .001” depth adjustments. I did find that with use, the positivity of the clicks vanished, but adjusting the tiny Allen-key set screw which presses the bearing fixed the issue.

With adjustments made and depth set, turn the motor on, and slide the handle/collet/case assembly to the cutter and the blades will trim, chamfer, and deburr the case in a couple seconds. Withdraw the handle, give it a half-twist counterclockwise to unlock, and the case falls free into the collection tray. Install another case and repeat. It’s that simple.

Changing Cartridges

A huge benefit that the Hornady trimmer provides is the included tooling to cover a wide variety of cartridges. Changing the trimmer over from one cartridge to another is simple. First, replace the collet with the correct one if necessary. Second, remove the clear protective chip guard and loosen the set screw which holds the cutter head onto the spindle of the motor. Loosen blade and pilot set screws, remove and replace pilot, then replace blades and re-install. Finally, reset cutting depth and you’re off to the races.

Hornady vs. Henderson

Since Hornady introduced their trimmer in early 2025, I’ve noticed numerous comparisons between it and Henderson’s excellent precision case trimmer. They are certainly in the same style and share some features, but there are a lot of differences too. I’ll leave it up to you to decide which you prefer, but here are some of those specifics:

Similarities

- Both trimmers use a motor-powered cutter and sliding collet, twist-lock handle assembly

- Both trimmers have an adjustable hard stop to set trim length

- Both trimmers use a cutting head that holds a pilot and two cutting blades

- Both can be fitted with a case collection tray

Differences

- Hornady trimmer uses a direct-drive motor, Henderson uses a belt drive

- Hornady cutter head slides over motor spindle, Henderson cutter heads insert into drive.

- Henderson offers cartridge-specific pre-set cutter heads, but they can be adjusted by user, Hornady’s trimmer intended for user adjustment.

- Hornady trimmer’s depth adjustment is dial-adjustable, Henderson uses a simple machine screw and nylon lock nut

- Henderson collets are inserted into removable handle then that is threaded into slide assembly, Hornady trimmer has a removable cap to retain collet

Power Trimmers Like the Hornady High-Speed, 3-in-1 Case Trimmer Are the Answer for High-Volume Reloaders

There are several popular types of case trimmers out there, ranging from crude to precise. When I started reloading ammunition with a Lee Classic Loader kit as a teenager, I used Lee’s simple case trimmer that, used in conjunction with their case length gauge, trims cases to standard trim length using a handheld drill. You can then, by hand, use a chamfer and deburring tool to dress up the case mouth. When a case is trimmed, substantial burrs develop on the inside and outside of the case mouth. These need to be removed for smooth bullet seating, loading, and overall reliability. Removing the burr and beveling the inside of the case mouth is referred to as chamfering, and “deburring” generally refers to removing the exterior burr and sometimes beveling the outside of the case mouth slightly.

The most popular hand-powered case trimmers are of similar design and are essentially small hand-cranked lathes. A collet grasps the case head on one end, and a handle is used to rotate the case against the cutter until the specified length is reached. These are precise and effective, but painstakingly slow. They also still require manual chamfering and deburring.

Electric powered trimmers have been around for a long time, and offer the speed and precision demanded by shooters handling hundreds or thousands of cases. For the average hobbyist or casual reloader, they have always been somewhat prohibitively expensive but, when fighting through the dull process of case preparation, they are a godsend. The less time you can spend on each case — while still getting precise results — the better your books will balance in the end. I’ve been using power case trimmers for almost 20 years, and can verify that a good one is worth every penny.

Final Thoughts

I’ve been thoroughly pleased with Hornady’s High-Speed, 3-in-1 Case trimmer in nearly every aspect, and I expect to be using it for years, and many thousands of pieces of brass, to come. High-end brass trimmers are expensive, and each design offers its own advantages and potential downsides. I can’t speak for all of them, but this Hornady trimmer doesn’t leave much to complain about — it’s a solid buy for high-volume reloaders.