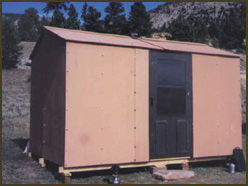

Tent camping has long been a favorite way to experience the natural wonders of the great outdoors. However, the novelty of sleeping on the ground-even with an air mattress-gets old quickly during extended trips. If you’re an outdoorsman who spends weeks or even months camping, consider building a tent platform.

This tent platform, designed for Outdoor Life, features a 2×4 frame covered in ½-inch-thick exterior-grade plywood. The really cool thing about this project is that the platform is completely portable: It can be erected and disassembled using only a screwdriver and hammer, and it folds up to fit in the back of most pickup trucks.

This 12- by 16-foot platform accommodates a 10- by 12-foot canvas wall tent. The extra 4 feet in front creates a small “front porch” that allows you to get out of the tent without stepping onto the ground. A detailed building plan of the platform is available online. Lumber and hardware will cost $450 to $500.

What You Need

- Six 4- by 8-ft. sheets of ACX ½-in. plywood

- Ten 12-ft. 2x4s (for joists)

- Four 8-ft. 2x4s (for sides)

- Four 8-ft. 2x4s (for legs)

- Twelve 6-in. Stanley LifeSpan strap hinges (No. 78-1515)

- Nine Stanley 3-in. utility hinges (No. 75-2060)

- Four Stanley 3-in. butt hinges with removable pins (No. 08-3031)

- Ten 3/8×8-in. Stanley eye bolts (No. 13-0290)

- Ten 5/16x2x5-in. Stanley square U-bolts (No. 13-4250)

- Ten 3/8×7/16-in. tee-nuts

- Twenty 5/16-in. wing nuts

- Twenty ¼-20x20mm insert nuts

- Twenty 1-in. washers

- Twenty ¼-20×1-in. flathead machine screws

[pagebreak] Building Guide

**1. Hinge the Frame **

Join two 8-foot 2x4s to form the platform’s 16-foot-long sides. Fasten together the 2x4s, end to end, using a heavy-duty 6-inch strap hinge. Next, saw ten 12-foot 2x4s into twenty pieces, each 70½-inches long. Join pairs of the 2x4s with strap hinges to create 10 floor joists, each 11 feet 9 inches long.

[pagebreak] 2. Build the Legs

Cut ten 2x4s to 10 inches, and another ten to 13½ inches. Screw the shorter 2x4s to the longer ones to create the legs. Use a C-clamp to hold the leg to the platform’s frame, then bore a 7/16-inch-diameter hole through both. Remove the clamp and hammer a tee-nut into the hole on the back of the leg.

[pagebreak] 3. Set the Floorboards

The surface of the tent platform is made up of six 4- by 8-foot sheets of ACX ½-inch fir plywood. Join the sheets with 3-inch narrow utility hinges to create three folding panels. For a stronger connection, bolt the hinges in place with short machine screws, washers and hex nuts. Apply marine varnish to the plywood.

[pagebreak] Field Assembly

4. Lay Out the Frame

Begin setting up the tent platform by first laying out its perimeter frame to form a 12- by 16-foot rectangle. Bring together each corner of the 2×4 frame, making sure the two hinge leaves fully interlock. Then, push the hinge pin down into place, locking together the two leaves and securing the frame’s corner. Repeat for the other three corners.

[pagebreak] 5. Attach the Legs

The tent platform is held off the ground by 10 legs, each 13½ inches tall. Attach each leg with an eye bolt. Thread the bolts through the frame and into the tee-nuts on the backs of the legs. Hand-tighten each bolt. Use the eye bolts to tie the tent down.

[pagebreak] 6. Install the U-Bolts

Each of the ten 11-foot 9-inch-long floor joists is supported at midspan by a single 2×4 leg. Attach the legs with square U-bolts and wing nuts. Tap each U-bolt through the holes with a hammer, then hand-tighten the wing nuts.

[pagebreak] 7. Secure the Floor

Bore an 11/32-inch hole 1 inch deep into the top of the 2×4 frame at each screw location. Use a 6mm Allen wrench to thread the insert nuts into the holes. Then bore ¼-inch screw-shank clearance holes into the plywood. Tighten the 20 screws.