We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

I was told growing up that a dull knife was more dangerous than a sharp one. When I was a kid, it was a head-scratcher for me, but when I really started using knives on my backpacking and camping trips and to dress and butcher game, it all came into focus. A dull knife takes a lot more effort to cut and usually ends up with you ‘’sawing’’ with the knife. Consequently, you can slip off and stick yourself. The lesson is that a dull knife is a worthless knife. This is why you need a knife sharpener.

So, the cure for what ails you is a sharp knife. But no matter how good the heat treat on the blade, or how sharp the factory edge, every knife will need to be sharpened. So where to begin? Sharpeners are available anywhere from five bucks to over $500. I have been sharpening knives since I was about 14 years old, and sharpening them professionally since 2015. In that time, I have used just about everything out there and I want to help you navigate the crowded knife sharpener market. Here are my picks for the best knife sharpeners, as well as picks from Greg Campbell, a custom knife maker, and Scott Einsmann, gear editor.

- Best Overall: Precision Adjust Knife Sharpener – Elite

- Best Electric: Work Sharp Ken Onion

- Best Professional: Wicked Edge Gen 4

- Best for Chef Knives: HORL 2

- Best Sharpening Stone: Smith’s Arkansas Stone

- Best for Kitchen Knives: Spyderco Tri-Angle Sharpmaker

- Best Whetstone: Keenbest Sharpening Stone

- Best Strop: Bacher

- Best Honing Rod: Noble Home & Chef

- Best for Your Pack: Work Sharp Pivot

Testing the Best Knife Sharpeners

We sharpened knives with varying blade angles and heat treats while evaluating the knife sharpeners on the following criteria:

- Speed

- Ease of use

- Consistency

- Edge produced

The Best Knife Sharpeners: Reviews and Recommendations

Best Overall: Precision Adjust Knife Sharpener – Elite

Key Features

- 15 to 30 degree angle guides

- Includes: 220, 320, 400, 600, & 800 grit diamond plates, ceramic plate, leather strop, and ceramic rod for serrations

- Adjustable in 1 degree increments

- Price: $139.95

- Great for sharpening pocket knives, kitchen knives, hunting knives, and broadheads

Pros

- Precise sharpening

- Easy to use

- Versatile

Cons

- Learning curve

Whether you need to sharpen a 2-inch pocket knife or an heirloom fixed blade, this is the best knife sharpener for the job. It can power through super steels and polish to mirror finish. I like that it’s easy to maintain a consistent edge angle and that the kit only has a few pieces. It’s also relatively inexpensive compared to similar sharpeners.

I rarely use the aggressive stones that are included in the kit, unless I’m repairing a chip. I start with the 600 grit, progress to 800 grit, and finish with the leather strop. You can go from a knife that won’t push cut paper to one that will split a hair in 10 minutes. Part of what makes sharpening go so quickly is how easy it is to rotate the stones to change grits. It’s also very easy to swap sides of the knife.

There is a learning curve to using this knife sharpener, but here are a few tips to help shorten the curve. Find the right angle by coloring the edge with a sharpie and making light passes with the stone until you find the angle where the stone removes the sharpie from the edge. Another option is to choose an angle you like and use the coarse stones to adjust your knives to that angle. Once you have an angle, the key is to use light, consistent pressure and long strokes. Remember to move the strop in one direction so that it doesn’t cut the leather. -S.E.

Best Electric: Work Sharp Ken Onion

Key Features

- Includes coarse, medium, fine, and extra fine belts

- Adjustable between 15 and 30 degrees

- Variable speed

Pros

- Can repair damaged knives

- Fast sharpening of any knife

Cons

- Not all users will want a convex edge

- Loud

This is a spin off of Work Sharp’s Original electric belt knife sharpener, but with some big upgrades that make it the most versatile sharpener on the market. With the blade grinder attachment, you can even dabble in knife making. Adjust from 10 degrees per side all the way to 35 on the semi-guided attachment. I still use my Wicked Edge, but this is my main tool now. Easy mirror polished, beyond razor-sharp edges on every type of knife, and it will also do scissors, machetes, axes, and even my straight razor. Like the other Work Sharp knife sharpener, this will give you a convex edge, and it will get it done fast. Repair broken tips, deep chips, and rolls in just a few minutes.

Read our full review of the best electric knife sharpeners to see more options.

Best Professional: Wicked Edge Gen 4

Key Features

- 12 to 28-degree angle

- Includes: 100, 200, 400, 600, 800, and 1000 grit diamond stones

- Adjustable in .5 degree increments

- Sharpens blades up to 15 inches long

- Price: $1000+

Pros

- Precise sharpening

- Easy to use

- Versatile

Cons

- Learning curve

No, it’s not cheap, but you can’t argue with the results. I bought a Pro Pack 1 for my sharpening business, and it was worth every penny. The evolution of that system is the Gen 4 sharpener. Perfectly mirror polished, hair whittling edges every time. I have sharpened nearly 2000 high-end EDC knives with mine, and it’s still going strong. Pick any angle from 12 to 28 degrees per side, clamp it in, follow the directions, and you’re going to get a level of sharpness that you’ve probably never experienced. The Wicked Edge gives the perfect v-edge, every time. If you plan to sharpen a lot of knives, or you want the mirror edge with the least effort, this is the way to go.

Read Next: How to Sharpen a Pocket Knife

Best Rolling: HORL 2

Key Features

- Price: $189

- Coarse and fine sharpening stones

- Magnetic knife holder

- 15 or 20 degree angle

Pros

- Very easy to use

- No sharpening experience necessary

Cons

- Not recommended for pocket knives

If you don’t want to spend months practicing how to sharpen a knife, this is the ultimate sharpening system for your kitchen knives. All you have to do is stick the knife to the magnetic angle guide, and then roll the sharpening stone back and fourth until you see a bur develop. Then flip the knife over and repeat on the other side. It takes minutes and there is no technique mastery necessary.

Best Sharpening Stone: Smith’s Arkansas Stone

Key Features

- Length: 4.75 inches

- Width: 1.25 inches

- Comes with carrying case

- Price: $14.50

Pros

- Precise sharpening

- Easy to use

- Versatile

Cons

- Learning curve

I cut my teeth on a Smith’s Medium Arkansas Stone. And for the price, you can’t beat them. There are some “pull-through” sharpeners out there for a little less than the cost of a knife-sharpening stone, but they really don’t do a good job, and they chew up your blade. The small 4 inch stone can be had for around $10, but the 6-inch stone is preferable for a little more money. This blade sharpener method will take some practice, and you might not get the results you want right off the bat, but when you master it, there is a deep satisfaction that comes from it. Learning to keep your angle consistent will be the biggest hurdle, but there are many good tutorials online, and Smith’s does make small guides to help you out in the beginning. Depending on your technique, you can either get a v-edge, or a slight convex from a stone. A very slight “rocking” motion at the end of each pass can produce a convex if you prefer.

Best for Kitchen Knives: Spyderco Tri-Angle Sharpmaker

Key Features

- Ceramic Stones: Medium (brown) and fine (white)

- Can be set to 30° (15° each side) or 40° (20° each side)

- Aluminum safety rods

- Can sharpen knives, scissors, and awls

- Price: $89

Pros

- Precise sharpening

- Easy to use

- Versatile

Cons

- Learning curve

Kitchen knives usually aren’t taking big hits, and really need more maintenance than anything. The Sharpmaker is perfect for maintenance. It comes with ceramic rods of differing grits, depending on how much material you need to remove. It’s also a semi-guided system and lets you choose from some preset angles. You hold the knife nice and straight and make alternating passes down each ceramic rod with a sweeping motion to get it sharp from the heel all the way to the tip. Again, it will take some practice, but this sharpener gives excellent results, and can bring you edge to a near mirror polish with practice. If your edge has some real damage, it may take some time to sharpen it out. The Sharpmaker doesn’t have a coarse enough rod to remove damage quickly. It’s worth noting that this system will work with blades of any size. You can put a nice v-edge on anything from a Case Mini-Trapper to a meat carving knife.

Best Whetstone: Keenbest Sharpening Stone

Key Features

- Two double-sides stones

- Silicon carbide construction

- 7”x2.2”x1” sized stones

Pros

- Sturdy and simple design

- Inexpensive cost

- Contains all you need to effectively sharpen your knives in one kit

Cons

- It comes with a set angle guide that may not work for every style of knife you sharpen

- At 7 pounds, it’s a little heavy for travel

The Keenbest Sharpening Stone is an inexpensive, easy-to-use set that comes with two whetstones, one with 400/1000 grit and the other with 3000/8000 grit. The heavy duty base is made of bamboo, with rubber on the bottom to keep it in place when sharpening — a convenience and a safety feature. The whetstones are two different colors, a light green and a light orange, allowing the user to quickly identify the proper stone. It also comes with a “resurfacer,” otherwise known as a flattening stone that is used to flatten the whetstones as they get worn away with use. Keenbest includes a leather strop and an angle guide — everything you need to sharpen and maintain your blades is included. Keenbest includes a helpful list of tips for using this system. There are more expensive stones on the market, but these stones are highly effective, and with a little patience and work, are great for getting that sharp cutting edge you’re looking for. -Greg Campbell

Best Strop: Bacher

Key Features

- Rough and smooth side

- 12.5 inches long

- 2.17 inches wide

- Includes four grits of stropping compound

Pros

- Plenty of surface area

- High-quality leather

Cons

- Some users might prefer two smooth leather sides

I use this strop daily for my leather working tools and for touching up my pocket knife between sharpenings. I keep a medium stropping compound on one side and a fine compound on the other. With this strop and the included stropping compound you can take an edge that’s sharp and bring it back to very sharp in just a few swipes. If you keep your tools sharp and never let them get dull, you won’t have to use a stone unless you do some damage. That’s why a strop is a must have-tool for maintaining your blades. -S.E.

Best Honing Rod: Noble Home & Chef

Key Features

- 2000/3000 Grit

- 11.5 inches long

- Ceramic

Pros

- Great for kitchen knives

- Easy to use

Cons

- Can break if dropped

Open my kitchen knife drawer and you’ll find this ceramic hone. I bought it after a friend of mine, who is a custom knife maker, recommended it. I use it to touch up my chef’s knife before every use and instead of sharpening weekly, I’m down to sharpening my kitchen knives monthly. Just like a strop, the key is maintenance. Keep your knives sharp, and you won’t have to sharpen them. When it comes to honing rods the most common mistake is using them the wrong way. If you are holding the hone in one hand as you quickly swipe the blade in the other, you’re doing it wrong.

The right way to use it is to put the tip of the hone on your cutting board, then while maintaining a consistent angle make even passes on each side of the blade. S.E.

Best for Your Pack: Work Sharp Pivot

Key Features

- 25 degree carbide sharpening blades

- 320 grit diamond sharpening surface

- Fine-grit ceramic rods

- Weight: 2.4 ounces

Pros

- Easy to use

- Versatile

Cons

- One angle

When your hunting knife gets dull while you’re boning out an elk, you need a sharpener that will quickly get you back to work. That’s where the Wicked Edge Pivot excels. It’s not a fancy sharpener and it’s not going to produce mirror edges, but when your knife is dull, it will make it sharp. At 2.4 ounces this palm-sized sharpener isn’t too big to keep in your pack. Since my hunting knife of choice is now a fixed blade, the Pivot has a permanent place in my kill kit. One of the keys to using this sharpener is to not press down on the blade, just use the weight of the knife for downward pressure as you pull the knife across the rods. -S.E.

Read Next: How to Sharpen a Knife

How to Choose the Best Knife Sharpener

My dad was a sushi chef and he started everyday by soaking his whetstones and bringing his knives to a fine edge. His stones are still being used to sharpen my kitchen knives and they’ll last for many years to come.

But they’re not the best knife sharpener for every job. On my knives made from high-rockwell stainless steels, I prefer an electric sharpener to repair chips and diamond stones for general maintenance. And sometimes, getting the whetstones prepped is a pain. So I’ll reach for a honing rod to quickly get a blade ready to cut, sorry dad.

Types of Knife Sharpeners

You can make a dull knife sharp with a car window or a thousand dollar sharpening stone. We’ve reviewed a lot of options between those two options and the trick is going to be determining which is best for you. Here are some pros and cons to consider for the three main types of sharpeners.

Electric Knife Sharpeners

Pros

- Sharpen knives quickly

- Easy to use

- Great for repairing chips

- Produce a convex edge

Cons

- Can ruin a knife quickly

- The convex edge isn’t ideal for all cutting applications

Guided Knife Sharpeners

Pros

- Easy to use

- Sharpen most knives

Cons

- Takes time to setup and use

Stones

Pros

- The ultimate sharpening flex

- Can produce a toothy or fine edge

- Don’t remove too much steel

Cons

- Learning curve

Honing a Knife versus Sharpening a Knife

A knife sharpener removes metal from a knife to create a new cutting edge. A honing rod refines an already sharp edge. Think of a honing rod or pull-through sharpener as maintenance tools for keeping your knife sharp. Even with consistent honing, your knife will eventually need sharpening by a stone or belt sharpener.

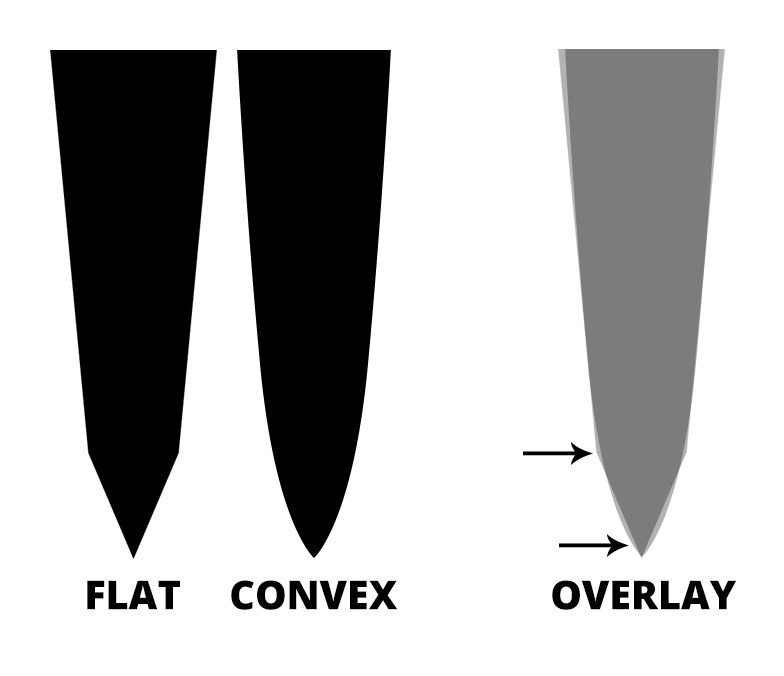

Type of Edge

There are two primary types of edges a sharpener can put on a knife, a v-edge and a convex edge. The v-edge has a cross-section that looks like a “V.” A convex edge has a slight curve to the bevel, like a “V” that curves inward slightly at the bottom. A convex edge is generally more durable, and less likely to chip or roll under heavy use, but they usually don’t feel as sharp as a v-edge of the same angle. Both types of edges can be made sharp enough to whittle hair, and both are great in the right application.

The last factor you should look at before choosing a sharpener is edge angle. To keep it simple, the smaller, more acute the angle, the sharper the knife will be, and the better the outright cutting performance. But, that performance comes at the cost of edge strength and stability. The lower your angle, the more likely you are to chip or roll your edge if you run into something hard like bone, or a staple in the cardboard, or a bullet fragment in your game meat. Many systems have angle guides that help you maintain a consistent angle across the entire edge, and they let you pick from a range of angles.

FAQs

Pull through sharpeners can do more harm than good. Some models are fine for light touch-ups, but they don’t really sharpen a knife. It’s much better to invest in a ceramic hone and learn how to use it properly.

The best way to sharpen a kitchen knife is to use a ceramic hone for touch-ups and a guided sharpening system like the Work Sharp Ken Onion knife sharpener.

Knife sharpeners work extremely well if you take the time to learn how to use them. The good news is best knife sharpeners in this review are all easy to use.

Final Thoughts on the Best Knife Sharpeners

Few things match the satisfaction of taking a rough edge to a polished edge that will split hairs. Whether you choose a manual knife sharpener like the Wicked Edge or an electric sharpener like the Work Sharp, you can produce a sharp knife that will give you the satisfaction of slicing paper with ease.

- Best Overall: Precision Adjust Knife Sharpener – Elite

- Best Electric: Work Sharp Ken Onion

- Best for Pocket Knives: Wicked Edge Pro Pack 1

- Best Sharpening Stone: Smith’s Arkansas Stone

- Best for Kitchen Knives: Spyderco Tri-Angle Sharpmaker

- Best Whetstone: Keenbest Sharpening Stone

- Best Strop: Bacher

- Best Honing Rod: Noble Home & Chef

- Best for Your Pack: Work Sharp Pivot