We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Selecting a fishing reel that fits both your needs and your budget can be a daunting task. Hundreds of options are available, and if you’re not sure what you’re looking for, it can quickly become overwhelming.

That’s why I got my hands on the top reels from the top brands in the fishing industry to put through a summer of abuse and tournament bass fishing. Here are picks for the best fishing reels after a year of testing.

Spinning

- Best Overall: Daiwa Ballistic MQ LT 2500D

- Best Value: Okuma Ceymar HD 2500HA

- Best Lightweight: Shimano Vanford 2500HG

- Abu Garcia Revo Rocket SP20

- Abu Garcia Revo Winch SP30

- 13 Fishing AL13 3.0

- Best for Trout: Pflueger President XT

- Best for Panfish: Daiwa Tatula MQ LT

Baitcasting

- Best Overall: Okuma Hakai DT 101H-A

- Best Value: Abu Garcia Revo SX LP

- Best Low-Profile: Daiwa Tatula Elite 100HSL

- Best for Saltwater: Shimano Tranx

- Shimano Curado MGL 151HG

- 13 Fishing Concept C2

- Abu Garcia Revo STX LP

How I Chose the Best Fishing Reels

Derek Horner

As a tournament bass angler, I spend most of my summer on the water, dialing in patterns and trying to perfect new techniques. With many hours spent on the deck of my bass boat, and the resulting stripped gears and sheared-off components, it’s become clear to me that I’m not easy on my gear. That’s probably a relief to you, though, because you can trust me when I say the reels below all stood up to the torture test.

Testing Baitcasting Reels

When it came to selecting the best baitcasting reel of the year, I obviously had a lot of options top consider. I decided to focus on price, durability, castability, and the feel of the reel. To keep things fair, I tried to keep all of the reels in the 6.0:1 to 7.3:1 gear ratio range. That range allowed me to use these reels for a wide variety of techniques rather than dialing in a specific technique for each reel.

Throughout the summer, I used all of these reels to fish popular bass fishing techniques from topwater, to jigs, to crankbaits, to chatterbaits in grass, and even carolina rigs. After a summer of sweeping hooksets and screaming drags, I feel confident recommending the reels below to any angler looking to upgrade their baitcasting reel.

Testing Spinning Reels

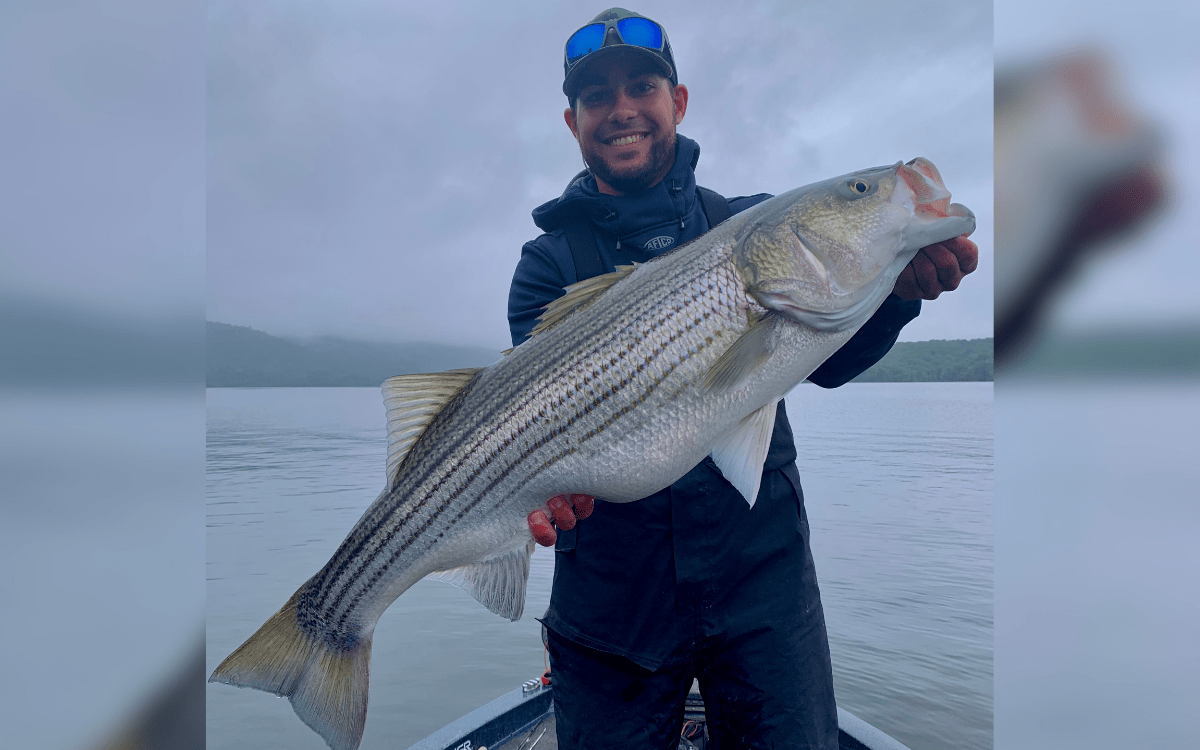

I spent months fishing for smallmouth, largemouth, stripers, and lake trout tearing drag and testing the quality of these reels. I feel very confident in telling you that each and every one of these reels deserves a shot to be on your reel seat.

Due to that fact, deciding which reels are better than the others was more difficult than I had ever expected. Thankfully, after a lot of thought and in-field research, I’m confident the reels below deserve the top spots.

Testing Saltwater, Trout, and Panfish Reels

The saltwater, trout, and panfish selections were made by Outdoor Life contributors who did dedicated testing in their respective fields of expertise. You can read their full reviews in the best saltwater baitcasting reels, best trout spinning reels, and best ultralight reels.

The Best Fishing Reels, Spinning: Reviews and Recommendations

Best Overall: Daiwa Ballistic MQ LT 2500D

Key Features

- Price: $229.99

- Gear Ratio: 5.2:1

- Weight: 6.9-Ounces

- Bearings: 2CRBB + 6BB + 1RB

- Line Capacity: 10/250 (Test/Yard)

- Drag Weight: 22-Pounds

Pros

- Incredibly smooth while reeling

- Castability

- A drag weight heavy enough to battle even the largest bass

Cons

- The gear ratio is a bit lower than other options, meaning a slower retrieve on the water

Derek Horner

The Daiwa Ballistic MQ LT 2500D is more than deserving of our best overall award. Throughout the summer of battling largemouth, smallmouth, lake trout, and even a 25-pound freshwater striped bass, the high-quality drag never showed even the slightest sign of slipping or failing. The quality of this reel can be felt with each turn of the handle, which fits perfectly in your hand with a well-thought-out handle design.

Coming in at just below 7 ounces, you don’t have to worry about the weight of your reel wearing you down throughout a long day on the water. A final piece worth noting with this phenomenal reel is the castability. The first time I reared back and fired out a ¼-ounce swimbait head with a 3.8-inch soft plastic swimbait on the back, I was stunned at just how far along the bluff wall it went. It was almost like I was long lining the bait, but in reality, I had simply cast it out there.

If you’re looking for a high-quality reel at a very reasonable price, I wouldn’t look any further than the Daiwa Ballistic MQ LT 2500D.

Best Value: Okuma Ceymar HD 2500HA

Key Features

- Price: $89.99

- Gear Ratio: 6.0:1

- Weight: 8.3-Ounces

- Bearings: 7BB + 1RB

- Line Capacity: 10/130 (Test/Yard)

- Drag Weight: 13-Pounds

Pros

- Very smooth while reeling

- Castability

- Deep spool for more line capacity

- High gear ratio for increased retrieve speed

Cons

- A fairly low drag weight

- At just over 8-ounces, it’s one of the heavier reels from the test

The Okuma Ceymar HD 2500HA might be the best value reel I’ve seen in years. For just under $100, it offers anglers an incredibly quality reel at a more than fair price. I was excited to get my hands on the Ceymar HD because it’s the only reel in the test with a price point under $100.

With such a low price point, you might assume the reel isn’t worth your time. That’s where you’d be wrong. While using the Ceymar HD throughout a fishing season, I loved its castability and smooth feel while retrieving. The only negative piece I have is that the drag did slip once or twice under the load of some hefty lake trout making a run towards tree tops 80 feet below.

It didn’t fail during that torture test, but it did bring forward an uneasy feeling for a moment. Outside of the torture test, the reel performed flawlessly against 5-pound smallmouth in heavy current and big largemouth taking my drop shot for a ride. The Okuma Ceymar HD 2500HA punched above its weight class in this test and is more than deserving of our best value award.

Read Next: Best Drop Shot Rods

Best Lightweight: Shimano Vanford 2500HG

Key Features

- Price: $249.99

- Gear Ratio: 6.0:1

- Weight: 6.3-Ounces

- Bearings: 7BB + 1RB

- Line Capacity: 8/140 (Test/Yard)

- Drag Weight: 20 pounds

Pros

- Quality components

- Smooth while reeling

- The most lightweight reel in the test

- A high-class drag weight

- A tall spool for a high line capacity

Cons

- The tall spool allows line to more easily get under the spool in the case of line twists

Derek Horner

When it comes to fishing an 8-hour tournament day, lightweight gear can make or break the day. The Shimano Vanford 2500HG is the perfect choice for a lightweight reel that still gives you a heavy drag and unmatched performance. You can fish with this reel all day without wearing yourself out, and you’ll cast easy knowing the reel won’t let you down once you set the hook.

The Vanford 2500HG also offers a smooth casting experience while still launching your bait further than you’d expect. The only negative I found with this reel was that the tall spool allowed for the line to get under the spool and jam whenever I ran into line twist while vertically jigging. While it’s an easy fix, it’s worth noting. As a final thought, the Shimano Vanford 2500HG truly impressed me with the smoothness of its drag while fighting a variety of different species throughout the summer. It’s certainly worth the money if you’re looking for a lightweight powerhouse reel to put on your favorite spinning rod.

Abu Garcia Revo Rocket SP20

Key Features

- Price: $199.95

- Gear Ratio: 7.6:1

- Weight: 7.3-Ounces

- Bearings: 9SS + 1RB

- Line Capacity: 8/120 (Test/Yard)

- Drag Weight: 11.4-Pounds

Pros

- The fastest gear ratio spinning reel in the test

- Smooth while reeling

- A large grip on the handle

- Small profile

Cons

- Drag weight is somewhat low

- Small spool size means less line on the spool

If you’re looking for a blazing fast retrieve, the Abu Garcia Revo Rocket SP20 is for you. At a gear ratio of 7.6:1, it’s the fastest spinning reel I’ve ever held. More surprisingly, it’s incredibly low profile, which is the opposite of what I expected when I saw the gear ratio. The handle is large compared to the reel’s size, but it doesn’t get in the way. Honestly, the handle size was helpful in finding the grip when first engaging the reel.

The biggest con with this reel is the low drag weight. At just under 12-pounds of drag, I had a few moments throughout the summer where the reel was simply outgunned by larger fish going on a long run. While I may have been outgunned, the 10-pound test I was fishing only failed once, which means the smoothness of the drag is worth noting. If you like fishing senkos or other weightless baits that require you to catch up to a fish from time to time, the Revo Rocket SP20 should be at the top of your list of reels to try out.

Read our full Abu Garcia Revo Rocket review to learn more.

Abu Garcia Revo Winch SP30

Key Features

- Price: $169.95

- Gear Ratio: 4.8:1

- Weight: 7.9-Ounces

- Bearings: 8SS + 1RB

- Line Capacity: 10/140 (Test/Yard)

- Drag Weight: 11.4-Pounds

Pros

- Low gear ratio makes this reel perfect for slow moving baits

- Smooth drag

- A high-quality grip and handle

Cons

- Drag weight is somewhat low

- A bit heavier than most of the competition

The Abu Garcia Revo Winch SP30 is perfect for slow rolling a small soft plastic swimbait or even a light wire spinnerbait. It offers the lowest gear ratio in the test, so if you’re looking for a reel to take advantage of slow-moving baits, look no further. While it is heavier, it’s still under 8 ounces, so it won’t wear you out if you’re throwing it for a few hours.

With a large spool, it offers a solid line capacity and good casting distance, especially with heavier baits. Similar to the Revo Rocket SP20, I’m not a huge fan of the light drag weight, as a heavier fish with large runs might take you to school. However, in those instances, I never had my 10-pound line break, so the drag was certainly smooth enough to handle heavy runs. The Abu Garcia Revo Winch SP30 is a great option at a solid price for an angler looking for a slow reel retrieve.

13 Fishing AL13 3.0

Key Features

- Price: $170.00

- Gear Ratio: 5.2:1

- Weight: 11.4-Ounces

- Bearings: 9BB

- Line Capacity: 8/260 (Test/Yard)

- Drag Weight: 16.5-Pounds

Pros

- A low gear ratio for slower moving baits

- A large spool for a high line capacity

- A solid drag weight at over 15-pounds

- Made for saltwater

Cons

- This reel is heavy, at over 11-ounces

- The grip is very large, sometimes hard to get a good grasp

The 13 Fishing AL13 3.0 is a dang big reel. Coming in at over 11 ounces, it’s heavy and bulky. The trade-off is a massive spool that increases your line capacity. This reel is another good option for those looking to throw slow-moving baits with a low gear ratio reel.

I prefer low-profile reels, so I personally wasn’t in love with the AL13 3.0. For heavier baits, it could be a good option for some anglers, because this reel can toss heavy baits a mile with the spool size as big as it is. However, with how heavy and bulky the build is, it’ll wear you down throughout a day of fishing. The drag performed well under load and didn’t slip or cause any issues while fighting large freshwater fish throughout the summer. While I wasn’t in love with the AL13 3.0, it’s still a quality option for anglers who prefer larger profile spinning reels.

Best for Trout: Pflueger President XT

Key Features (25 size)

- Braided Line Capacity: 140 yards of 6 pound

- Max Drag: 8 pounds

- Reel Weight: 6.6 ounces

Pros

- Lightweight

- Sealed drag

- Smooth 9+1 bearing system

- Reasonably priced

Cons:

- Weak drag

- Limited line capacity

The Pflueger President XT may not have the best of any one feature, but its combination of lightweight design with rugged capability and smooth performance allows for impressive functionality and quality. Top that off with a surprisingly low price tag for a reel with these features, and you have the most well-rounded trout spinning reel around.

A classic reel designed for all-around freshwater angling, the Pflueger President series has been around for years. The 9+1 bearing system of the President has always stood out as impressively smooth for a reel at this price point, and the President XT retains that signature feel. Where the XT improves upon the original is in the component materials and drag system.

Featuring corrosion-resistant aluminum for the shaft and pinion gear, as well as a carbon handle, the XT is incredibly light at only 6.6 ounces for the 25 size. While that alone is a nice improvement, the standout feature of the President XT is the sealed drag system. Sealed drags are primarily included in reels designed for saltwater use but having one in your trout reel has several distinct advantages. Throwing on the best waders and getting into the river is one of the most popular and common ways to target trout, and it’s a technique that exposes your gear to a lot of potential hazards. Having a sealed drag can help keep your reel smooth and prevent grit and grime from the river from entering the drag system. The XT also has a look that combines classic and modern aesthetics, with its carbon and aluminum components set off by a rubber cork handle. The old President had a signature wooden handle that was sadly eliminated in recent years, and the cork handle on the XT helps return some of that classic wood aesthetic.

The combination of lightweight design and durability with functionality and appearance help make the Pflueger President XT the perfect all-around trout reel. When combined with a reasonable price tag, the President XT is hard to beat if you’re shopping for the best trout spinning reels.—Kevin Hughes

Best for Panfish: Daiwa Tatula MQ LT

Key Features

- Woven high-density carbon resin body

- Air rotor and air bail

- Fold-down handle

- 5+1 ball bearings

- Gear Ratio: 6.2:1

- Max drag: 11 pounds

- Line capacity: 250 yards (4-pound mono) 160 yards (6-pound mono)

- Weight: 5.8 ounces

Pros

- Easy to palm

- Smooth drag

- Quick drag inertia start-up when a fish is on

- Extremely lightweight

Cons

- Only comes with one spool

The “LT” in Daiwa Tatula LT stands for “light” and “tough,” and the reel is precisely that. Constructed of Daiwa’s high-density carbon ZAION material, the result is an incredibly light reel while remaining rigid and strong. The Daiwa Tatula LT 1000D-XH also features a ZAION Air Rotor for weight reduction and added rigidity, making the Daiwa Tatula lighter and easier to handle without fatigue over the long course of a full day of fishing.

The Tatula LT was my top pick because of its value and performance. What I liked most about it was the drag pressure (11 pounds) and quick drag start-up inertia from the first bend in the rod tip. The reel handled everything from panfish to walleyes, bass, smaller northern pike, and sheepshead with ease. The larger specimens I caught on my Mississippi River trip tested the drag, which remained buttery smooth. Matched with a feathery rod like the St. Croix AVID Panfish, the diminutive 5.8-ounce reel weight proved a great fit to keep the entire setup light in hand with maximum sensitivity.—Jim Edlund

The Best Fishing Reels, Baitcasting: Reviews and Recommendations

Best Overall: Okuma Hakai DT 101H-A

Key Features

- Price: $199.99

- Gear Ratio: 7.3:1

- Weight: 5.9-Ounces

- Bearings: 6BB + 1RB

- Line Capacity: 12/110 (Test/Yard)

- Drag Weight: 20-Pounds

Pros

- Incredibly smooth while reeling

- Castability

- Durability

Cons

- The small tuning magnet is in a tough to reach spot with the drag wheel

Derek Horner

The Okuma Hakai DT 101H-A is one of the best baitcasting reels I’ve ever gotten my hands on. It checked all of the boxes for castability, durability, profile, feel, and even price. At $200, the Hakai DT is a perfect option for anglers looking for a high-quality reel without the high-end price tag.

The Hakai DT quickly earned its spot in my main rotation of reels early in the summer. I personally loved it as a dock skipping reel because it’s incredibly easy to tune and control the amount of line coming off the spool on those long skips to the dark corners of a shallow dock. The cast is smooth, and the distance I got out of an easy flick surprised me on the first cast I made. After months of hooksets and bouncing on the boat deck, this reel still looks and feels as good as new. The Okuma Hakai DT 101H-A not only survived my torture test, it rose to the occasion and is more than deserving of the best overall award.

Best Value: Abu Garcia Revo SX LP

Key Features

- Price: $169.95

- Gear Ratio: 7.3:1

- Weight: 7.4-Ounces

- Bearings: 9SS + 1RB

- Line Capacity: 12/130 (Test/Yard)

- Drag Weight: 25-Pounds

Pros

- Castability

- Durability

- Easy to tune

- High drag weight

Cons

- Reel handle material gets slippery in rainy conditions

The Abu Garcia Revo SX LP offers some amazing features for a bargain price. Coming in under $170 with the feel of a $250-$300 reel, it’s more than worth your money. The Revo SX casts easily once tuned, which was also a breeze, and has a drag weight that’s ready to fight even the meanest largemouth bass.

The reel is fairly low-profile, which surprised me from Abu Garcia, which historically offers larger-profile reels. As a fan of lower-profile baitcasters, I am a huge fan of how this reel felt in my hand while casting and retrieving. The only negative I ran into while fishing with the Revo SX was that the reel handle got slippery while fishing in rainy conditions. The material is a soft rubber composite, unlike some other options out there that offer a spongier material. Outside of the grip material, it was difficult to find a single other thing I disliked about this reel. The Abu Garcia Revo SX LP offers an amazing reel at a great price, making it more than deserving of our best value award.

Best Low-Profile: Daiwa Tatula Elite 100HSL

Key Features

- Price: $249.99

- Gear Ratio: 7.1:1

- Weight: 6.7-Ounces

- Bearings: 7BB + 1RB

- Line Capacity: 12/150 (Test/Yard)

- Drag Weight: 11-Pounds

Pros

- Very smooth while reeling

- Very smooth while casting

- Durability

- Low-Profile

- T-wing system for castability

Cons

- A fairly low drag weight

- The small tuning magnet is in a tough to reach spot with the drag wheel

Derek Horner

The Daiwa Tatula Elite 100HSL might be one of the best all-around baitcasting reels I’ve ever used. Daiwa touts the T-Wing system as the best way to increase castability, and I found that to be spot on. With even a light cast, my bait would launch towards my intended target with ease. This reel feels like butter during the casting and retrieving process.

My favorite thing about this reel, however, is just how low-profile it is. It easily fits in your hand and is light enough to hold and cast for an entire tournament day without feeling worn down. The only two cons to this reel are the low drag weight and the small tuning magnet. With the drag weight coming in at 11 pounds, you’re a bit outgunned when chasing big bass in Texas or Florida. With the small tuning magnet, the drag makes it tough to reach. You have to put forth some effort and patience to truly make micro-adjustments, which can be frustrating in the heat of a tournament. Still, with the smoothness you’ll feel and quality components in this reel, it’s worth every penny. Pair that with how it feels in your hand, and you’ll see why it’s the best low-profile baitcasting reel available.

Best for Saltwater: Shimano Tranx

Key Features (150HG size)

- Weight: 6.7 ounces

- Line Capacity: 150 yards of 20-pound braid

- Bearings: 3+1

- Max Drag: 13 pounds

- Gear Ratio: 7.2:1

- MSRP: $219.99

Pros

- Extremely durable

- High-end gearing and seal

- Lightweight

- Smooth

- Large range of sizes (150-500)

Cons

- Limited drag strength

- Limited tuning ability

The Tranx lineup from Shimano has gained a well-earned reputation for withstanding anything thrown at them. The smallest reel in the series, the 150, is no exception. Despite its lightweight and smaller size, this reel still feels rock solid in your hand. It’s designed to cast and fight fish in the salt all day, every day.

The Tranx 150 is a reel for anglers pushing their gear to the limits. It lacks some of the smoothness and featherlight feel of the Chronarch G, but it more than makes up for its durability. The delicate internal components are housed within a rigid metal frame that prevents flex and warping, making this reel ideal for intense fights and long days on the water. It also utilizes Shimano’s CoreProtect technology, which is a protective coating that prevents corrosion and adds extra strength to the core components of the reel.

While the reel does boast a smooth carbon dag, the stopping power is somewhat lacking at 13 pounds. That’s not terrible, but it is a little less than one would expect for a reel designed with such heavy-duty use in mind. That said, this reel will have more than enough power for most inshore applications. Additionally, the Tranx comes in several sizes, from 150 all the way up to 500. The 150 is ideal for inshore casting applications, the 300 is perfect for bucktailing fluke and throwing big topwaters for stripers, and the 400 size with the power handle is the best saltwater baitcasting reel for deep jigging. The larger sizes provide significantly more drag and are a great option for expanding beyond light inshore use. —Kevin Hughes

Shimano Curado MGL 151HG

Key Features

- Price: $209.99

- Gear Ratio: 6.0:1

- Weight: 6.5-Ounces

- Bearings: 6BB + 1RB

- Line Capacity: 10/120 (Test/Yard)

- Drag Weight: 13-Pounds

Pros

- Quality components

- Lightweight

- Smooth casting

- Easy to tune

Cons

- A fairly low drag weight

The Shimano Curado MGL 151HG is an impressive baitcasting reel coming in just over $200. For reels in that price range, I always look for quality, smooth casting and retrieve, and the ability to easily tune the reel. The Curado MGL 151HG checked all of those boxes and continues to impress me with its versatility.

With a 6.0:1 gear ratio, this reel really can do almost everything. I’ve recently been throwing crankbaits with it as the fall bites heats up, but I also used it while dragging a carolina rig during the dog days of summer. It excelled in both instances. Really, the only issue I found with this reel is a fairly low drag weight. At 13-pounds, it’s likely to land 99-percent of the largemouth and smallmouth bass you’ll come across with ease, but in the case of catching larger fish like musky, pike, or even freshwater striped bass using bass gear, you’ll find yourself outgunned quickly. If you’re not afraid of losing your toothy bycatch from time to time and are mainly concerned with landing that lunker bass, the Shimano Curado MGL 151HG is worth your consideration.

13 Fishing Concept C2

Key Features

- Price: $229.99

- Gear Ratio: 7.5:1

- Weight: 5.8-Ounces

- Bearings: (2ACHS+6SSBB) + 1RB

- Line Capacity: 12/125 (Test/Yard)

- Drag Weight: 25-Pounds

Pros

- Lightweight

- High drag weight

- Smooth casting

- Durability

Cons

- Tuning required some patience

- Spool size is somewhat shallow when using heavy line

The 13 Fishing Concept C2 has been a favorite reel of mine for a couple of years now. It’s the only reel in the test that I already had on the water experience with prior to this year. I have always looked at the Concept C2 as a heavy bait and heavy line reel. The bulldog drag coming in at 25 pounds will pull in a foul-hooked log if you want it to. It’s easy to cast and lightweight as well, making it nice to lock in your hand for a day of flipping and pitching.

The tuning magnets take a bit of work to dial in, but once they’re dialed, you won’t have to make any adjustments until you change baits. Another small issue I have run into is that you’ll have to watch your line capacity while fishing. If you spool up and run this reel hard for a few weeks and get to about a half spool, you’ll start to see your backing on the next long cast. If you’re like me and change your line often, that’s not so big of a deal, but if you like to spool up and leave the line on for a while, you might get a bit tired of re-spooling. Regardless, the 13 Fishing Concept C2 is one of my ‘daily driver’ reels that’s been in my arsenal. I know that I can confidently lock it in my hand for a tournament day and have confidence that the reel won’t let me down when a lunker locks down on the end of my line.

Abu Garcia Revo STX LP

Key Features

- Price: $229.95

- Gear Ratio: 6.7:1

- Weight: 7.8-Ounces

- Bearings: 10SS + 1RB

- Line Capacity: 12/130 (Test/Yard)

- Drag Weight: 25-Pounds

Pros

- Versatile

- High drag weight

- Smooth casting

- Durability

Cons

- Fairly shallow spool size

- Tuning took longer than anticipated

The Abu Garcia Revo STX LP is another great do-it-all reel. With the gear ratio just below 7.0:1, it’s great for almost any technique you’d like to throw. If you’re trying to slow roll a spinnerbait, or trying to burn a shallow diving crankbait, the Revo STX LP will do the trick. With the 10SS bearing system, it’s incredibly smooth casting, and the retrieve doesn’t leave much to be desired. The handle is easy to find and grip, but similar to the Revo SX LP, the grip material does get a little slippery in rainy conditions.

The line capacity doesn’t leave much room for half spools, but if you keep your spool filled, it will be plenty of line for any cast you make. While tuning the Revo STX LP, I ran into trouble getting the fine tuning magnet to set. I’d get it where I’d want it to be, make a few casts and then have to re-adjust the small magnets again. Perhaps I should have made a larger adjustment with the bigger tuning magnet prior to trying to dial in the small magnets, but it was a bit frustrating. Outside of the tuning issues, the Abu Garcia Revo STX LP impressed me on the water all summer long. With the heavy drag, I never felt outgunned when setting the hook, and I was able to fish whatever technique I wanted knowing that this reel would get the job done.

How to Choose a Fishing Reel

Sizes

Spinning reels will come in different sizes, which is primarily related to spool size. If you need a lot of line capacity or are using heavy pound test, you’ll use a large reel. But, if you’re using light line a smaller reel is all you need. Manufacturers vary on how they designate reel size, which can be confusing for new anglers. The most common sizes you’ll see are 500, 1000, 2,000, 2500, 3000, 4000, 5000. For bass anglers the 2000, 2500 and 3000 sizes are the most common. For panfish and trout 500 and 1000 are common. Saltwater anglers use everything from 2500 to 5000.

Like spinning reels, baitcasters come in different sizes and most manufacturers use the same references for their sizes, but there are outliers. In general, you’ll see size 70, 150, 200, 300, and 400 baitcasters offered. The lower the number, the smaller the reel. The all purpose bass reel is the 150 size. It offers good line capacity and balances on most rods. If you’re fishing heavy line or need more line capacity you can step up to a 200 or 300 reel. They’re commonly used for things like fishing big swimbaits.

Gear Ratios

A reel’s gear ratio refers to how many times the spool turns for each turn of the reel handle. A 7.1:1 gear ratio means the spool makes 7.1 rotations for each rotation of the handle.

The trend in baitcasting reels is toward faster and faster retrieval rates. Where a 6.3:1 used to be an all-around option, it’s now considered slow. The 7.1:1 has taken over as the do-everything ratio, and 8.1:1 is the choice for powerfishing.

Spinning reels are similar, but generally have slower gear ratios. They typically have a 5:1 to 6:4 ratio.

Right or Left Retrieve Baitcaster

While some anglers will tell you there’s a right or wrong answer to this selection, there’s not. It truly comes down to personal preference. For example, I’m right-handed and cast a baitcaster with my right hand on the reel. As the lure hits the water, I move the rod over to my left hand and crank the handle with my right hand.

I know that seems like an overly complicated system, but it’s not uncommon. If casting with my right and retrieving with my left felt natural, believe me, I would do it. I would suggest trying to retrieve with your non-dominant hand to start because it is more efficient, but if it doesn’t feel natural, don’t fight your fate. —Scott Einsmann

Final Thoughts on the Best Fishing Reels

This year’s crop of casting and spinning reels was impressive, and I was shocked at how well each performed throughout the summer and tournament season. There isn’t a single reel in the test that I wouldn’t recommend adding to your arsenal. When picking the right one for you, consider the gear ratio, profile of the reel, and the spool size you’ll need for different styles and techniques you plan to use it for.

Spinning

- Best Overall: Daiwa Ballistic MQ LT 2500D

- Best Value: Okuma Ceymar HD 2500HA

- Best Lightweight: Shimano Vanford 2500HG

- Abu Garcia Revo Rocket SP20

- Abu Garcia Revo Winch SP30

- 13 Fishing AL13 3.0

- Best for Trout: Pflueger President XT

- Best for Panfish: Daiwa Tatula MQ LT

Baitcasting

- Best Overall: Okuma Hakai DT 101H-A

- Best Value: Abu Garcia Revo SX LP

- Best Low-Profile: Daiwa Tatula Elite 100HSL

- Best for Saltwater: Shimano Tranx

- Shimano Curado MGL 151HG

- 13 Fishing Concept C2

- Abu Garcia Revo STX LP