We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

In the last 10 years we have seen a number of cartridges introduced that all have similar design characteristics. They have a relatively short, minimum-taper cartridge case with sharper shoulder angles, moderate capacity, fast twist rates, what would seem to be heavy bullets for the case size, and chamber throat designs that are long and tight.

A few examples of these cartridges are the .300 WSM, 6.5mm Creedmoor, 6mm Creedmoor, and most recently the .224 Valkyrie. All of them deliver downrange performance and accuracy beyond anything that would be expected from a cartridge of their size. So what exactly is behind this shift from traditional cartridge designs with a big case pushing a projectile at high velocity?

Traditional Cartridges

Let’s start by looking at the design characteristics of several long-standing traditional cartridges. This design philosophy, for the most part, has used a big case with a lot of taper and a modest shoulder angle with a lot of propellant behind a medium-weight projectile. This formula is about generating speed.

A lot of case taper was considered necessary for reliable extraction, and modest shoulders were easy to produce. Some examples are the .22/250 Remington, .243 Winchester, .264 Winchester Magnum, and .300 Winchester Magnum. These cartridges all have moderate to slow twist rates and relatively modest weight projectiles. The bottom line is their designers wanted bullets to go fast. The tables on p. 45 show a comparison of these four traditional cartridges and their modern counterparts.

As you can see, all the newer cartridges have sharper shoulder angles. They all have less case capacity than a comparable older cartridge. They all have the same lead angle of 1.5 degrees. They all have a lead diameter barely over the projectile diameter. They all have faster twist rates. And they all shoot heavy, high-ballistic-coefficient projectiles. Considering their smaller case capacity, they all produce muzzle energy levels quite close to that of much larger capacity cases in the same caliber. What I could not show in the tables is that all the newer cartridges have much less body taper than the older cartridges. Finally, all of the newer cartridges have established reputations for very good to incredibly good accuracy with out-of-the-box ammunition and rifles.

All About the Bullet

Today, cartridge and ammunition designers are putting much more emphasis on projectile performance characteristics. If I could sum up this philosophy, it would be “let the bullet do the work.” In other words, design a cartridge that can use a heavy, very aerodynamic projectile, launch it at a more modest velocity, and let the bullet aerodynamics provide the downrange ballistics. This is the common thread binding the new efficient cartridges listed above. The benefits to the shooter are actually better downrange ballistics despite the lower muzzle velocities, less recoil, and longer barrel life.

The old-school approach to cartridge design—large case and going fast—resulted in very heavy charges of slow propellants. In general, with this approach the propellant is not completely burned by the time the projectile exits the barrel. The result is faster barrel wear, severe muzzle blast, and heavy recoil.

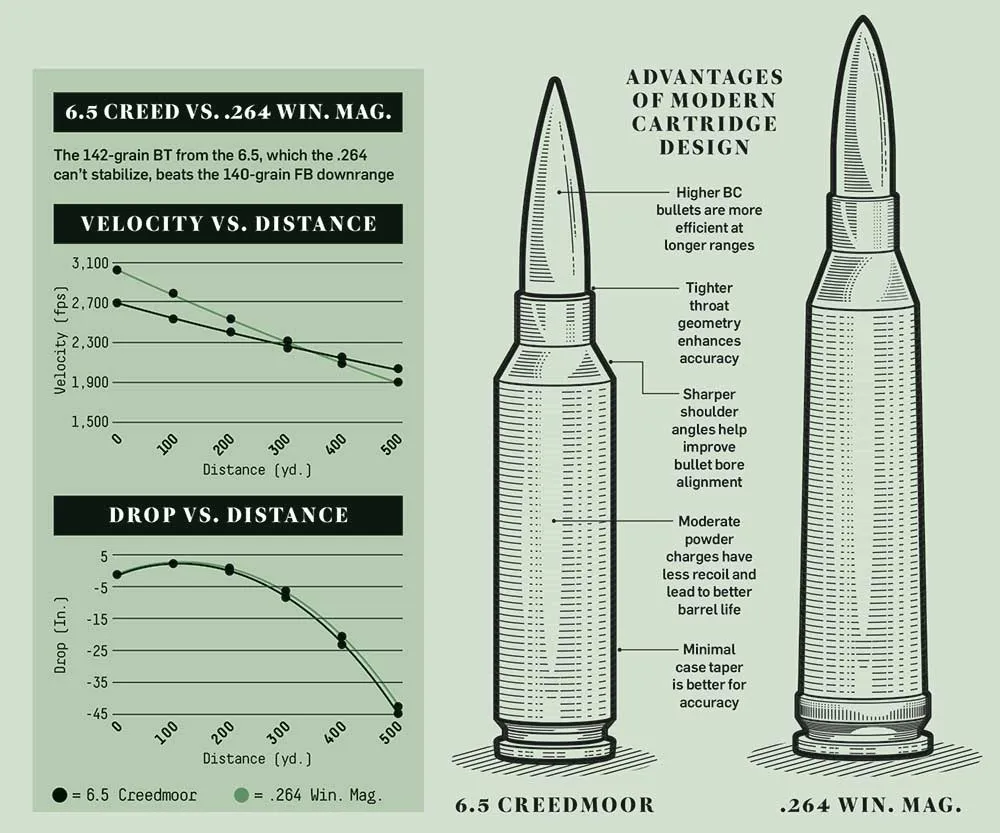

To take a concrete example, let’s compare the ballistics of the .264 Win. Mag. with a 140-grain flat-base projectile to the 6.5 Creedmoor with a 143-grain boattail projectile (see charts above). You might cry foul, because those are two very different bullets, but hear me out. The .264 Win. Mag., because of the 1:9-inch twist it was designed around, can’t adequately stabilize more bullet than a 140-grain flat-base Spitzer. Even adding a boattail would result in a marginally stable projectile that would likely have stability problems on a cold day. Not so with the Creedmoor, because of the 1:8-inch twist.

As you can see, the 6.5 Creedmoor quickly makes up the 330 fps deficit in muzzle velocity it has with the .264 Win. Mag. There is also very little difference in the trajectory of each cartridge despite the 330 fps difference. If the graphs were taken to greater distances, the 6.5 Creedmoor would leave the .264 in the dust. This is the value of emphasizing the projectile design as part of the cartridge design. The 6.5 Creedmoor will, for all practical purposes, perform with the .264 Win. Mag. It does so with less recoil, 15 to 20 grains less propellant, and about three times the barrel life.

New Accuracy Standards

The approach to designing an inherently accurate cartridge has also changed. The traditional way to get an accurate cartridge-chamber combination was to have no lead or throat in the chamber, the bullet seated right up to or actually into the rifling, a tight chamber-to-cartridge neck fit, and a sharp and concentric crown on the muzzle. Lead angles tended to be a little random, from 1.5 degrees to up to 15 degrees. Little attention was paid to the cartridge shape or throat design as it pertained to the projectile. Throat or lead diameters were allowed to be anywhere from .003 to .007 inch larger than projectile diameter.

These types of lead diameters allow a lot of room for a projectile to wander around while trying to get seated in the rifling. This can lead to the projectile entering the rifling at an angle relative to the axis of the bore. This angle is called principle axis tilt (PAT). It is the angle between the line of flight of the projectile and the axis through the center of the projectile from the rear to the point. PAT defines the angle of attack or, put another way, the angle the bullet is flying at relative to the line of flight. The bigger this angle, the less accurate the bullet will shoot.

Minimizing PAT

Ballisticians have gained better insight into projectile dynamics and how they affect performance. Along with the quality of the construction of the projectile, jacket concentricity, and consistent core swaging, the PAT of the projectile has to be controlled and minimized to obtain top accuracy. If the projectile enters the rifling at an angle, it will travel down the barrel at that angle, and it will leave the muzzle at that angle. The projectile will be starting out behind the curve for best accuracy before it ever leaves the gun.

Better understanding the relationship between the projectile and barrel, designers are now designing cartridges and chambers with an eye toward controlling the entry of the projectile into the rifling and thus the PAT. The optimum lead angle into the rifling has been pretty well established for quite some time as 1 degree 30 minutes, or 1.5 degrees. Many new cartridges have a very tight lead or throat with a diameter that is only .0005 inch bigger than nominal projectile diameter. This tight fit between the projectile and lead forces the projectile to enter the rifling as straight as possible. It is an old wives’ tale that “jump to the rifling,” or bullet travel prior to entering the rifling, is bad for accuracy. That just isn’t true. There can be a significant jump to the rifling if the lead diameter is designed to be very close to the projectile diameter. The only limitation to throat length is getting too much jump to the rifling and having a projectile running into the rifling at a velocity that damages the jacket.

The quest to improve accuracy and limit PAT is another reason we see cases with minimal body taper and sharper 30- to 35-degree shoulders. These two things aid in forcing the cartridge case to align itself better with the axis of the barrel. The minimal taper and sharper shoulder don’t allow the cartridge to lie off center in the chamber as much as a more tapered, shallow-shoulder-angle case. This in turn further helps to limit and control the PAT of the projectile.

So, have these changes in design approach and philosophy really brought shooters better-performing, more-shootable cartridges? Another look at cartridge specs below provides the answer. The .224 Valkyrie does not match the .22/250 with the heaviest projectiles that the .22/250 can shoot, but the Valkyrie burns about 8 to 10 grains less powder in the process. The .224 Valkyrie can fire the heaviest projectiles made in .224-inch caliber. Not so the .22/250 without a rebarrel and a faster twist. For long-range shooting, the .22/250 can’t touch the Valkyrie. Likewise, the 6mm Creedmoor can run away and hide from a .243 Winchester. The .300 WSM produces the same performance as the .300 Win. Mag. but does it with 6 to 8 grains less propellant. In every one of the comparisons, the newer cartridge will have longer barrel life, less recoil, and less muzzle blast because of its more efficient design. Lastly, at this point there is little argument about the outstanding accuracy of any of these new cartridges. Shooters have never had it so good.

New Cartridge Specs

| Cartridge | .224 Valkyrie | 6mm Creedmoor | 6.5 Creedmoor | .300 WSM |

| Twist Rate (in.) | 7 | 7.5 | 8 | 10 |

| Shoulder Angle (deg.) | 30 | 30 | 30 | 35 |

| Lead Diameter (in.) | .2246 | .2435 | .2645 | .3099 |

| Lead Angle (in.) | 1.5 | 1.5 | 1.5 | 1.5 |

| Case Capacity (gr. H2O) | 30.9 | 50 | 52 | 79 |

| Bullet Weight (gr.) | 88 | 103 | 143 | 190 |

| G1 BC | .545 | .512 | .625 | .595 |

| Muzzle Velocity (fps) | 2,675 | 3,050 | 2,700 | 2,875 |

| Energy (ft.-lb.) | 1,398 | 2,127 | 2,315 | 3,487 |

Traditional Cartridge Specs

| Cartridge | .22/250 Rem. | .243 Win. | .264 Win. Mag. | .300 Win. Mag. |

| Twist Rate (in.) | 14 | 10 | 9 | 10 |

| Shoulder Angle (deg.) | 28 | 20 | 25 | 25 |

| Lead Diameter (in.) | .2245 | .2463 | .268 | .315 |

| Lead Angle (in.) | 2.0 | 1.5 | 2.0 | 1.5 |

| Case Capacity (gr. H2O) | 43 | 52.8 | 82 | 89 |

| Bullet Weight (gr.) | 60 | 1000 | 140 | 180 |

| G1 BC | .240 | .405 | .465 | .450 |

| Muzzle Velocity (fps) | 3,650 | 2,960 | 2,940 | 2,950 |

| Energy (ft.-lb.) | 1,625 | 1,960 | 2,684 | 3,475 |